Products

Parametric Design Software Drives Mold Manufacturing Automation and Efficiency

Tebis America’s third release of Tebis 4.1 features new interactive features for the everyday mold builder at IMTS 2022, including complete collision control and faster programming.

Read MoreMetric-Diamond-Coated End Mills for Graphite Electrode Machining

As the industry continues to adopt graphite electrodes, Crystallume introduces its high-precision, tight-tolerance coated end mills to meet moldmaking needs.

Read MoreLarger Capacity Auxiliary Injection Unit Introduced

Mold-Masters has extended the capabilities of its E-Multi auxiliary injection platform, introducing the new larger capacity EM5 model.

Read MoreThree-Axis Machining Center Aids Mold Builders With Reduced Cycle Times, Improved Surface Finish

The VMX30Di three-axis machining center from Hurco Companies has been designed to help job shops focusing on batch production or mold and die work be more productive and profitable.

Read MoreProbing Line Comes With Multichannel Radio Transmission for Highly Accurate Die and Mold Measurements

Marposs is demonstrating its high-precision probes with radio transmission at IMTS 2022, which, through automatic detection of machine axis position, can achieve part positioning and accurate part measurement.

Read MoreAll-in-One CNC System Advances Speed, Accuracy, Operability for Moldmakers

Enhanced functionalities regarding surface roughness and roundness measurements, faster axes drive speeds and more ergonomic controls exemplifies Mitutoyo’s latest RTX Roundtrace Extreme.

Read MoreSmart Training Solutions Presented to Industry Employers, Educators

NIMS is highlighting its on-the-job Smart Training Solutions at the Smartforce Student Summit booth at IMTS 2022.

Read MoreSoftware Remotely Monitors, Measures Critical Process Conditions

Sensert from ATC Diversified Electronics, is a modular approach to whole-plant remote process measurement with customizable thresholds, monitoring conditions including level, temperature, pressure, flow and current via existing sensors.

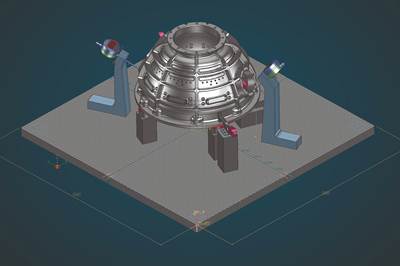

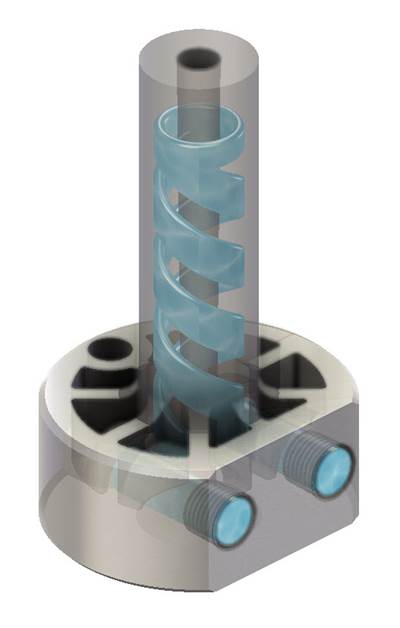

Read MoreConformal-Cooled Sprue Bushings Line Expanded

PCS Company has added a 3/4-in radius for the U and B Series bushings options.

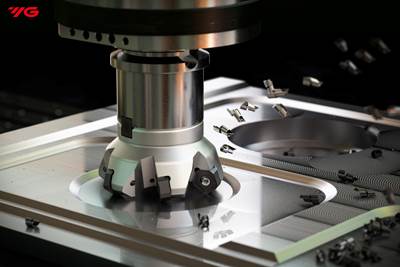

Read MoreRough and Mirror-Finish Face Milling Performed with Same Cutter

Live demonstrations will be given for YG-1’s FM10 PNMU indexable inserts and cutter at IMTS 2022, displaying the cutting tool’s ability to face mill and ensure a high surface finish in the same cutter, an important benefit for mold builders.

Read MoreFive-Axis Machine Demos Challenging Aerospace, Medical and Mold Applications

Multiple machining demonstrations showcasing Grob System’s G350 Generation 2 Universal Machining Center capabilities will be featured at YG-1 Tool’s booth at IMTS 2022.

Read MoreFast Wire EDMs Exhibit Removal of 3D-Printed Metal Parts From Large Build Plates

At IMTS 2022 EDM Network is showcasing its mid-sized, four-axis Fast Wire EDM machine, with three to four times faster cutting power.

Read More

.jpg;maxWidth=300;quality=90)