Products

Mobile Data Logger for Toolmaking and Production

D-System is a data logger from Hotset America that records the energy balance of water circuits in a mold.

WatchEasy-to-Use CNC Control With Redesigned Graphical Interface

Kitaumura’s Arumatik-Mi control system, featuring a revamped, modern GUI, simplifies programming, part setup and machining for operators of all skill levels.

Read MoreFace Mill Holder With Damping Vibration Control Supports Far-Reaching Operations

Big Kaiser, a member of the Big Daishowa Group, offers the new SDF57 arbor-style face mill holders, what it claims is the largest and longest milling tool, which could have important benefits for moldmakers.

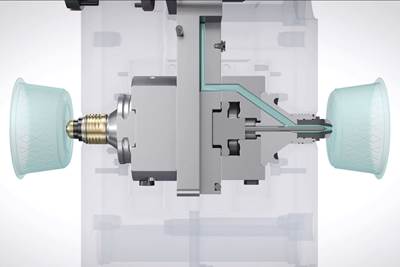

Read MoreCompact Stack Mold for Thin-Wall Packaging

Oerlikon HRSflow says the patent-pending design allows the use of smaller injection molding machines while still promising the high output a stack mold tool.

Read MoreReamer Reconditioning Service Restores Cutting Tools to OEM Specs

Monaghan Tooling Group’s Diatool service includes replacing all blades, grinding a fresh bevel geometry, refurbishing the body of the reamer and coating the blades if required.

Read MoreSingle-Shot Nozzle Guarantees Efficient Injection Temperature Control

The Single Shot H6300 from Hasco offers an optimal price-to-performance ratio for small- and medium-sized injection molding applications.

Read MoreLinear Height Gage for Mold Measurements is Highly Digital

Compared to previous models, the latest Mitutoyo LH600F/FG systems feature several new digital features that enhance its accuracy and funtionality.

Read MoreInch-Size Solid Carbide Shoulder/Slot Mills

Walter USA brings an expansion to its solid carbide milling offering for roughing, finishing and milling with new tools for universal application.

Read MoreCMMs Give Moldmakers Precision, Sustainability, Ergonomic Operation

The new generation of Zeiss Prismo precision measurement devices meet speed, flexibility, sustainability and productivity demands.

Read MoreOptical Cutting Tool Setter Measures in Constrained Spaces

The Marposs VTS SF-45 is designed for noncontact, optical measurement of small, complex-shaped cutting tools in micromachining, semiconductor or moldmaking applications.

Read MoreRoughing, Finishing Aluminum-Specific End Mill Line Expansion

Extended range of Sandvik Coromant’s CoroMill Dura versatile solid end mills engages stable cutting, small burr, good surfaces and minimal vibration.

Read MoreSurface Finishing Probe Accurately Evaluates Workpiece Surface Finish/Roughness

Soon-to-be-released Verisurf 2024 software will feature a Renishaw Revo SFP2 solution to evaluate a surface finish range of 6.3 to 0.05 micrometers.

Read More

.jpg;maxWidth=300;quality=90)