RJG Partners with Southern Union State Community College

SUSCC’s newly updated classroom and lab space will allow RJG to provide students with the latest in hands-on training technology.

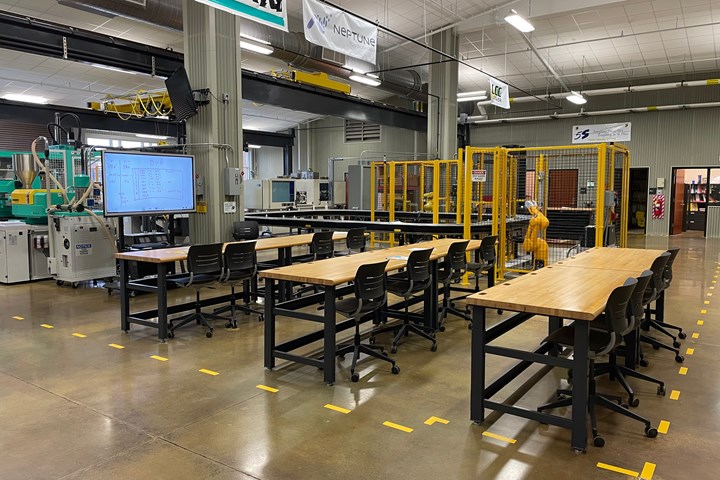

RJG (Traverse City, Michigan) has partnered with Southern Union State Community College (SUSCC, Wadley, Alabama) to bring RJG’s injection molding training to the Center for Integrated Manufacturing.

SUSCC’s newly updated classroom and lab space will allow RJG to provide students with the latest in hands-on training technology. There are currently three fully equipped RJG injection molding machines in the facility along with a large variety of auxiliary equipment and robotics.

Courses taught in this facility will include Fundamentals of Systematic Injection Molding, Decoupled Molding Workshop, Master Molder I and II, Advanced eDART Training and more. Courses are led in-person by experienced RJG instructors.

“We are thrilled to have this opportunity to work with such a prestigious center for continued manufacturing education,” says Shane Vandekerkhof, director of training and consulting at RJG. “We always strive to offer our students positive environments equipped with the latest technology to promote growth and learning that they can immediately put to use.”

“We are excited to partner with a company as highly regarded as RJG,” says SUSCC’s president Todd Shackett. “They are renowned as the premier systematic injection molding company in the industry, and their expertise will help bring our program to the next level. I am looking forward to seeing our students and industrial partners benefit from this opportunity.”

Related Content

-

MMT Chats: 5 in 5 with Neu Dynamics

MoldMaking Technology editorial director Christina Fuges chats with Kevin Hartsoe, president of Neu Dynamics to reveal their five best practices for improving efficiencies in culture, technology, process, measuring success and staying competitive ... in 5 minutes.

-

LSR Platform Meets Critical Medical Molding Needs

NPE2024: Recent updates to Mastip’s Aquilo platform highlight how its design — from consistent thermal profile to uniform cooling — has made it successful for medical industry projects.

-

MMT Chats: Molds, Molding, Marketing and Membership

MoldMaking Technology Editorial Director Christina Fuges chats with Eric Hecker, Sales and Project Engineer for Eifel about his focus on sales and marketing, the move into molding, technology and training trends and his mission to help increase membership in Mold Technologies Division of SPE. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.