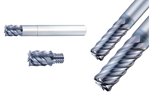

Flat Bottom Drill Supports Stable Counterboring Action

The OSG Phoeniz PDZ-3D is key to producing counterbores in mold bases with enhanced chip breaker geometry and precise finishing capabilities.

OSG USA Inc. announces the expansion of the company’s Phoenix PDZ offering with the addition of the new PDZ-3D indexable flat drills. The flat bottom drills feature enhanced chip breaker geometry, resulting in improved chip formation and evacuation. The broad lineup includes standard socket head cap screw sizes, enabling fast and stable drilling of counterbores in mold bases.

Phoenix PDZ’s flat bottom cutting edge configuration is compatible with a wide range of applications — drilling (including inclined and curved surfaces), counterboring, turning and more. It offers high-precision finishing on flutes, improves rigidity, efficient chip evacuation and reduces cutting force thanks to its four-corner insert design. It is available in inch and metric sizes.

Related Content

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

.png;maxWidth=300;quality=90)