EOS North America Celebrates Delivery of 1,000th 3D Printing Machine

Company reflects on more than 30 years of innovation and success in industrial 3D printers and additive manufacturing.

EOS North America, a technology supplier in the field of industrial 3D printing for metals and polymers, has delivered and installed its 1,000th machine in the North American market.

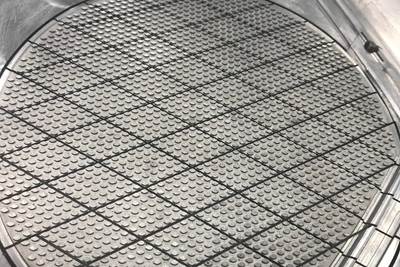

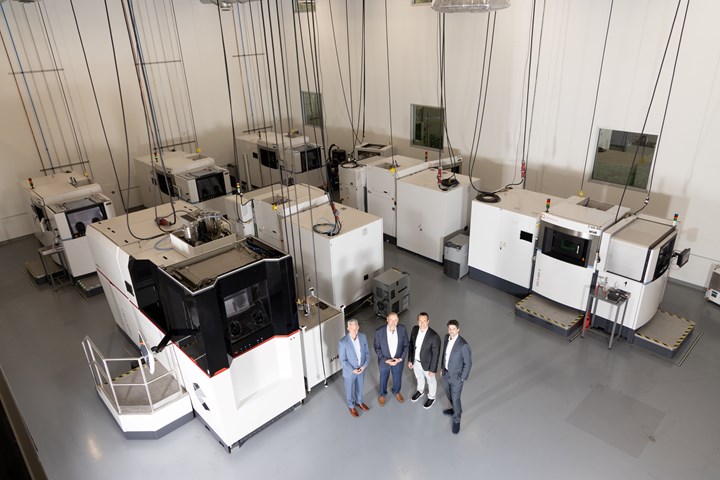

The milestone printer—an AMCM M4K from EOS’ AMCM business unit—is a large-scale, four-laser, high-productivity system, installed at Sintavia, a large metal additive manufacturer focused on the production of advanced propulsion systems for the aerospace, defense and space industries. EOS says the printer’s ability to 3D print applications up to one meter high is a unique feature of the AMCM M4K, which, a few years ago, was not possible.

“Constant innovation, consistency between machines and industrial-scale production dependability are why aerospace manufacturers of tomorrow rely on EOS,” says Brian Neff, CEO of Sintavia. “While this AMCM M4K represents the 1,000th machine in North America for EOS, it also represents the 17th EOS machine for Sintavia. Their machines form the foundation of our company’s manufacturing technology, and we are thrilled to be part of this milestone achievement in EOS’ history.”

EOS says the delivery also comes at a time when additive manufacturing (AM) is experiencing incredible market growth. A 2021 report from Lux Research anticipates that the AM market will reach $51 billion by 2030, up from $12 billion in 2020.

“This achievement is a significant milestone in the history of EOS and a testament to the accelerating adoption of AM in North America,” adds Andrew Snow, senior vice president of EOS North America, and one of its longest tenured employees. “As the proliferation of AM continues, we remain the leading innovator of hardware, materials, services and education aimed at strengthening the successful adoption and advancement of AM as a mainstream manufacturing process.”

EOS Award Presentation.

EOS was founded in April 1989 by Dr. Hans Langer in Gräfelfing, Germany, a small municipality south of Munich. By 1990, global brands like BMW were using EOS’ Stereos 400 stereolithography system, and within five years the company had introduced its first powder bed-based laser sintering system for manufacturing prototypes from plastic. The organization continued to develop and produce new, increasingly innovative industrial 3D printers in the years that followed while also undertaking a global expansion, establishing a presence in Italy, the U.K. and Finland. The company founded its North American headquarters in Novi, Michigan, in 2001. Today EOS North America also has its technical center in Pflugerville, Texas, and its materials engineering and production center at Advanced Laser Materials (ALM) in Temple, Texas.

Since its founding, EOS says it has continually innovated, collaborated and worked to advance the capabilities of AM leading to its current, robust ecosystem of products and services. From hardware, software and materials development and production, to its Additive Minds team of applied engineers, EOS’ experience and end-to-end offerings of products, services and training are designed to support organizations at each step of their AM journey—from start to part.

“When customers purchase from EOS, they are installing mature technology that leverages more than three decades of experience, as well as complete support for all of their AM requirements,” adds Snow. “While our industry looks vastly different than it did over 30 years ago, one thing has remained: EOS continues to serve as the industry leader, pushing industrial 3D printing in new, groundbreaking directions.”

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRead Next

How to Improve Mold Venting with Metal Additive Manufacturing

Patented 3D-printed mold insert design rapidly evacuates gases while preventing plastic flash-through, eliminates costly maintenance and need for press-side temperature-control units.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)