AMBA Reveals Work Capacity Tool

AMBA's Work Capacity Tool is an innovative resource now available to help mold manufacturers share and fill capacity when needed.

Photo Credit: American Mold Builders Association

The American Mold Builders Association (AMBA) announces the launch of the AMBA Work Capacity Tool — an innovative resource now available to help mold manufacturers share and fill capacity when needed. Designed specifically for AMBA member shops, this online, members-only tool enables a mold builder to locate open capacity in over-capacity situations and, conversely, fill open capacity when work is needed, thereby helping to fuel sustainability and growth.

One year ago at the AMBA Conference in Grand Rapids, Michigan, a group of AMBA members started a conversation on a common struggle in their companies — the need for a means to even out the ebbs and tides in their operations. That is how the capacity tool concept was conceived, according to AMBA president Don Dumoulin of Precise Tooling Solutions.

“If we could develop a tool where individual shops could share needs or wants of machining, polishing and EDM — all of the things it takes to make a tool in today’s environment — then we could level out the capacity for all of our shops,” Dumoulin recounts.

The newly designed, user-friendly AMBA Work Capacity Tool enables mold manufacturers to log open capacity over a 90-day period in over 50 areas of operation, including special machines and additional services. Members are encouraged to update capacity every 30 days, with automatic reminders sent to help keep the information current. From three-, four- and five-axis milling (including the ability to select size ranges) to EDM, polishing, design and more, a simple click of the button connects members with shops that meet their needs, including direct links to email for quick communication and rapid results.

“Our ability to quickly find open capacity we need help with will be a valuable resource to help provide more continuity during busy stretches. Conversely, if we have the open capacity to fill, being able to advertise that inside of a trusted network is equally valuable to our business,” says Tyler VanRee, Legacy Precision Molds Inc..

Shops searching for open capacity simply hit the “Search Work Capacity” button on the AMBA homepage, log in and search by date(s), areas of operation, location or multiple states. The search function has the ability to perform a search in multiple categories. Once finished entering information, the search engine instantly pulls up the matching results, including company address, capabilities and contact information for immediate access.

Tom Barr of TK Mold & Engineering Inc. says, “Currently, we have a small group of mold shops that we can pick up the phone and ask what their capacity is. The Capacity Tool will open us up to the ‘best of the best’ in our industry!”

The AMBA team worked diligently over the past year to bring this new resource to its members and created a “how-to” tutorial located on the AMBA website for ease of implementation. “Sharing best practices, benchmarking operations and discussing challenges have long-been the hallmarks of the AMBA network,” states Kym Conis, AMBA managing director. “The new Capacity Tool now enables members to share work, resources and even personnel more easily and with greater resolve.”

“The best part of this is that it is our industry helping our members,” Dumoulin adds. “It’s the best way to make our industry strong in the face of global competition.”

Related Content

Decoding Reshoring: Motivations, Challenges and Technological Influences

Harry Moser, founder and president of the Reshoring Initiative, sits down for a Q&A on the motivations behind reshoring decisions, offering insights into economic, strategic and regulatory considerations.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

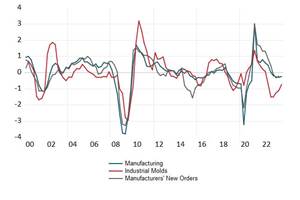

Read MoreNavigating Economic Resilience and Consumer Trends

Consumer behavior provides mold builders insight into the evolving market dynamics of goods and services that helps strategic planning.

Read MoreU.S. Economy Indicates Prospects for Moldmakers

An examination of the U.S. economy suggests its resilience against a recession, yet a mixed outlook for moldmaking and plastics persists.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)