When Is 3D Printing Cost Effective?

Hype continues to surround additive manufacturing. These three factors can help determine whether a part is worth 3D printing.

Digging into metal additive manufacturing quickly reveals how expensive it can be, as some parts produced using incumbent technologies, such as laser sintering and binder jetting, can cost thousands of dollars. If there's one lesson Matt Sand, President of 3DEO, a Los Angeles, California-based metal AM parts supplier, has learned over the last few years, it's that cost is everything when it comes to serial production.

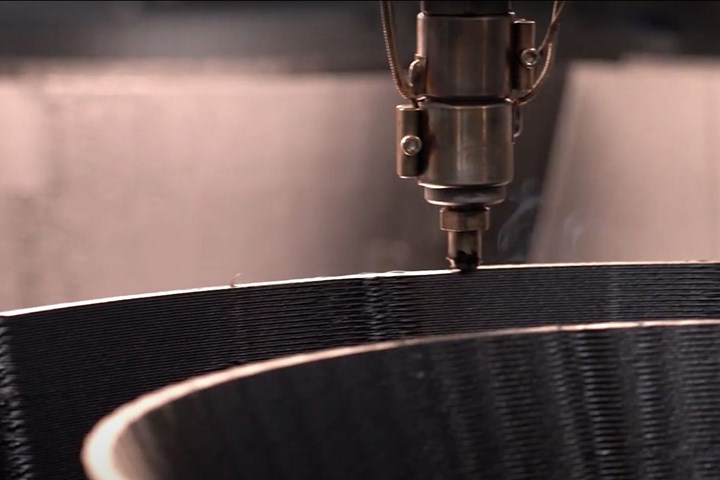

“If you're not in the ballpark on cost, you might as well not even play the game because there's no way to get into production without being cost competitive with conventional manufacturing techniques,” Sand says. “If you are not cost competitive, you're not at the table,” So, to get the total cost structure down, 3DEO developed an end-to-end manufacturing process around Intelligent Layering, a very low-cost metal additive manufacturing technology the company’s founders invented. Based on binder jetting technology, Intelligent Layering uses a proprietary spray system to bind the entire layer, and then uses a CNC end mill to cut the perimeter of the part and any internal features. (Read more about 3DEO’s technology and company strategy.)

Although 3DEO’s Intelligent Layering process offers a new take on additive, the company’s differentiator is that “we are not trying to sell machines, we’re only selling parts,” Sand says. The competition for its additive process is not metal 3D printing; it's traditional manufacturing. 3DEO is competing against CNC machining and metal injection molding and is already cost competitive with both of these technologies when it comes to small and complex metal parts, according to Sand.

There are three key factors he considers in determining whether it will be cost-effective to 3D print a given part:

1. Part Size

Is it bigger/smaller than a golf ball? One thing Sand has learned over the last few years is that as part size increases, the cost increases on an exponential curve.

Smaller (golf ball-sized) parts manufactured traditionally are price competitive. However, as the part size starts to reach softball size and greater, the cost skyrockets. It’s not uncommon in laser sintering for very large parts to cost $20,000 or more.

2. Assembly

Is the cost of assembly less than the cost of printing a consolidated part? Sand believes there is often a disconnect from reality when it comes to parts consolidation. “For example, a customer wants a five-piece automotive assembly printed as one piece. What they typically overlook is that the cost of the individual components and assembly is still very low,” he says. “The total cost of the metal 3D-printed part needs to be less than the total cost of the assembly. Given consolidated assemblies are large, it’s usually much more expensive to print versus assemble.”

3. Complexity

Does the part have complex features like conformal cooling, and is it likely to require substantial postprocessing? Conformal cooling is a hot trend in additive manufacturing, but 3DEO tries to be realistic with interested customers. The reality is that high-value tools are the best fit, because when it comes to laser sintering (the most common method used to make conformal cooling channels) the cost is high and the after-print surface finish still needs postprocessing.

3DEO’s strategy is not to provide the near-net shape component, but instead, provide the block with the channels already created. They focus on where CNC adds value and where 3D printing adds value. 3DEO believes that if you're going to have to finish that block anyway, then there's no point in trying to achieve extremely tight tooling tolerances.

“For example,” Sand says, “if the part needs to be a hemisphere, we’ll print the block with the internal channels, so the customer can have the conformal cooling, and ship the block to the customer in an unfinished state because they have to machine it anyway. This then brings the cost of the tool from thousands of dollars down to hundreds. If you don't have to achieve extremely tight tolerances, it's a lot less expensive. These tooling inserts can be very low cost from creating internal channels, but still allow the customer to reap the benefit of 3D printing.”

Related Content

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read More3D Printing Innovates Hot Runner Manifold Design

Metal 3D printing combined with a conventionally machined manifold block overcomes flow shadows on valve gates and offers faster color changes while providing closer system pitch centerlines between cavities.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More