MMT Blog

Why Choose a Valve-Gated Hot Runner?

Moldmakers need to be aware of how different gating technology can affect their customers when designing a hot runner system into a mold.

Read MoreSecrets to Using Ultrasonic Profilers

Moldmakers have been reluctant to invest in ultrasonic profilers due to their cost and a lack of understanding on how they work. But are they missing out on an opportunity to reduce overall polishing time by more than 60 percent?

Read MoreThe Heat is On

A survey of the industry reveals what moldmakers have on their hot runner wish lists this year, as well as what new products and technologies hot runner companies predict are going to be "hot" in 2001.

Read MoreProfiting From the Changing ISO 9001 for Moldmaking, Molding and OEM/End Users

ISO 9001:2000 is here - are you ready?

Read MoreCan't We All Just Get Along?

MoldMaking Technology's EAB dispenses advice on how to improve the often-tumultuous relationship between moldmakers and molders.

Read MoreWeb Development 101

In today's marketplace, an Internet presence is a necessity for any business to survive. However, thinking it through completely is important in order to make your site a destination stop on the Information Superhighway.

Read MoreGetting Quality Heat Treatment

Consultation with the heat treater regarding the material, mold configuration and processing variables is invaluable for maximizing tool life and cost efficiency.

Read MoreIntegrating Hot Runners Into Stack Molds

With stack molds becoming a more popluar technique in molding, moldmakers need to become aware of the many considerations involved in order to make hot runner integration successful.

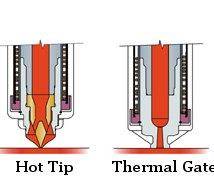

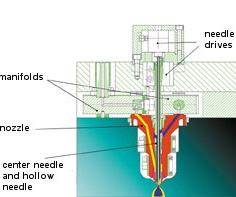

Read MoreHot Runners and Valve Gate Systems: A Moldmaking Team

Valve gates provide several advantages when using hot runners, including better appearance, safety and an overall better product. There are several types of valve gates, and it is important to choose the right one for your project.

Read MoreGoing Against the Grain: Low Cavitation Vs. High Cavitation

An injection mold expert speaks out against high-cavitation molds. There is a time and a place for them, he contends, but they should not be chosen for financial considerations alone.

Read MoreGovernment Without Consensus: What it Means for Industry

The results of November's election will have a lasting impact on both the moldmaking and plastics industry. As a result, Industry groups such as SPI will have to find new ways to deal with government.

Read MoreQuality Certification for Moldmakers and Molders - Keeping Procedures Current With Quality Standards

The role of management systems is to enable the business to accomplish its goals. However, moldmakers need to ensure that their procedures are current with quality standards in order to meet those goals.

Read More