Secrets to Using Ultrasonic Profilers

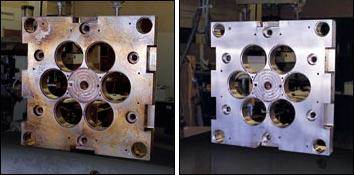

Moldmakers have been reluctant to invest in ultrasonic profilers due to their cost and a lack of understanding on how they work. But are they missing out on an opportunity to reduce overall polishing time by more than 60 percent?

There are two reasons why many companies are reluctant to use ultrasonic profilers. For one thing, the profiler doesn't always appear to be cutting on the first try. The second reason is the high cost of such machines. The truth is that in the hands of an experienced veteran, an ultrasonic profiler can easily cut overall polishing time on intricate parts by 60 percent or more. The key is knowing how ultrasonics work - which stones to use, what stone shape and size is best and which machine and technique to use.

Any company whose production of intricate parts equals 10 percent should consider buying an ultrasonic profiler. Any company whose intricate parts make up 30 percent or more should have several machines in use already. Intricate parts include molds that produce such things as electrical connectors, small medical parts and anything with small bosses and stock savers - especially jobs made from extra hard steels with a lot of rib work.

A company whose production of intricate parts is only 10 percent may still find it hard to validate the expense of such a machine. However, it can still pay off. One shop owner purchased an ultrasonic profiler after a veteran showed him cavities that had been taking 2.5 hours apiece that now only took 45 minutes from start to finish. The owner realized that this machine would prove to be the difference between making deliveries on time and being late.

Three Types of Ultrasonic Profilers

Not all ultrasonic profilers are the same. There are basically three main types of ultrasonic profilers on the market today - air powered, the old style with a large hand piece and the new style with a smaller hand piece. The larger the hand piece, the larger the crystal it holds and therefore the more cutting power these machines have. Air powered ultrasounds are the exception, having no direct drive crystal but using air pressure instead.

The reason that old-style machines have a larger hand piece is because they contain a crystal which vibrates when voltage is applied. This vibration can be as much as 20,000 cycles per second and this is where the concentrated cutting power of the ultrasound comes into play. With an ultrasound, the most experienced operators can bench any shape into any hardness of steel or weld quickly and accurately by using the proper combination of cutting tools and power settings.

Whichever type of machine you purchase, be sure you have tested it thoroughly, using these two tests to try out a new machine.

- Put a stone into the holder and try it on some steel - Can you stop the tip of the stone from vibrating with a 30 percent downward hand pressure? If you can, then don't buy that machine - it's just an expensive noisemaker and not a dependable cutter. The best machines still cut aggressively at 50 percent downward hand pressure before they start to stop.

- Test number two is the squealing. How loud is the stone squealing as it cuts? The louder the better! Be careful not to be confused by talk of higher cycles per second. High cycles are not the only thing that matters when selecting an ultrasound. If the stone tip keeps on vibrating after a load is put on - and proves it with a loud squealing - this is the workhorse that you're looking for.

Stones - Lengths, Shapes, Positioning and LED Feedback

The next most important item is the type, size and shape of the stones being used. Super hard EDM stones and RA stones are the only two types of stones you will ever need when ultrasounding. As there are dramatic differences between manufacturers, you want the stones that will cut the most under pressure, break the least and then leave the finest scratches when finishing.

The reason that many people say ultrasonic profilers don't cut has actually more to do with the size and shape of the stone being used than anything else. Here is the secret to making stones work - the tip must be able to move freely. It sounds simple enough, but this secret can be quite tricky to understand in practice.

Experience has shown that the best shape is a ," x 1/8" stone, 2.75" long, dressed in such a way that the stone is only full size where it is held in the machine and everything else tapers down evenly to a tiny point about .010" x .030" at the end. The tip must weigh nothing for 20,000-plus cycles per second to occur freely or else the weight of the tip will absorb the vibration and may even cancel the cycles out.

The proper position for a stone to be clamped in an ultrasonic profiler is in such a way that it is held at a 90 degree angle from the hand piece. You will find that the cutting power is multiplied 10 times or more when the stone is held at 90 degrees than when it's held straight forward. This is possibly due to a "cracking of the whip" effect - by holding the tip of the stone off to one side, the operator actually multiplies the tip's cutting power, whereas aligning the stone with the centerline of the hand piece produces no such additional multiplication.

LED feedback is displayed by the LED indicators on the machine's front panel and tells you how well the machine is in balance with the stone. Machines equipped with LED indicators are easy to use. Any time the LEDs are a multiple of two (i.e., two or four LED lights on) then the machine is operating internally at maximum ease for that power setting.

Consequently, an odd number of LEDs can indicate a growing imbalance, possibly because the stone is getting shorter, impacting the freedom of the vibrations. Some stones that worked well only seconds earlier now won't work at all because of some change in the overall length of the stone (the center of weight moves forward in direct proportion as the stone wears down and thereby slows down the tip vibration). When this happens, the operator has no choice but to redress the stone - making the tip once again as light as possible and also removing as much weight from the stone as possible. The operator can then slowly turn up the power until either operating performance is reestablished or a piece of the tip explodes off. In the case of an explosion, the physics of the cycle speed and power have broken off that part of the stone which was not in harmonic agreement with the length of the crystal's cycle.

When the LED indicators stay on zero even though you have turned the power up to full speed, then either the stone's shape is incorrect (the center of the stone's weight has moved too close to the tip and away from the clamp where it should be), or a connection is loosening. Either way, the end result is going to be an overheating of the crystal inside the hand piece with no cutting occurring.

When trying to fix stones that won't work properly, keep the tip of the stone weighing nothing and remove as much weight as you can from the rest of the stone. If the stone continues not to work, remove the stone from the holder, remove the holder from the ultrasonic hand piece and thoroughly clean all contact points with a solvent. Dry the hand piece completely and tighten every-thing back down until it all locks solid - there can be no loose connections or dirt anywhere on any contact points or the cycles will hit a "dead" spot and stop. Make sure that the stone is pushed as far into the holder as it will possibly go to make solid contact with the bottom of the stone holder's slot. Also make sure that it is clamped as tightly as possible. Ensuring that the stone length, weight and shape are in balance with the vibrations coming from the hand piece is the secret to having great cutting power.

There are only two main reasons for using ultrasonic profilers. One is to achieve a 60 percent timesavings over conventional polishing in intricate parts. The second reason, which is actually more important than the first, is that a veteran using an ultrasonic profiler properly will allow shop owners to make impossibly short deliveries that otherwise would not be achievable.

Related Content

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreRead Next

Cleaning Molds, Part III Ultrasonics Make Life Easier

Is there a “perfect” cleaning system for molds and tooling that would allow a significant reduction in labor hours and tooling damage while providing consistent cleaning results?

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)