MMT Blog

How to Request Accurate CAD/CAM Data

The Amercian Mold Builders Association offers moldmakers a guideline for customers to follow when submitting CAD/CAM data.

Read More2000 Asia Trade Mission Follow-up: Lessons Learned

After doing their homework overseas, moldmakers candidly discuss the impact that last year's trade mission has had on their businesses a year later.

Read MoreKing Systems, Plastics Technology Division - Developing A Competitive Edge Never Ends

By investing in both technology and employee skills, King Systems, Plastics Technology Division, combines the customer service advantages of a small-sized moldmaker with the cutting-edge skills needed to succeed.

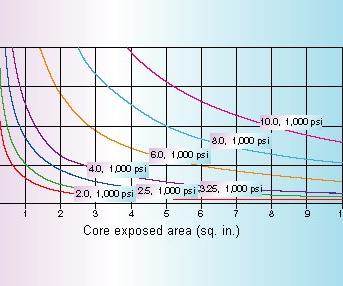

Read MoreMold Side-Actions: How, Why and When They Work

Understanding the effects of injection on the core, slide and associated components is critical to selecting the best side-action methods for a given application. This first of two articles will discuss the basic physics underlying all side-actions.

Read MoreGetting Specific: Narrowing Down the ISO Standards

The ISO 9001:2000 standards can be intimidating, but by breaking out what directly affects the industry, moldmakers can achieve certification faster.

Read More3-D Mill Software Brings Moldmaker Up to Speed

By reducing the time needed for EDM and CNC work, a moldmaking company was able to reduce costs and increase its business.

Read MoreMoldmaker-Invented Chiller Keeps Workpieces Cool Without External Coolants

A quest to improve the dry grinding process yields a chilling system that improves accuracy and increases production.

Read MoreThe Argument for Horizontal Machining Centers

Although VMCs are widely used, HMCs offer more flexibility, versatility and a number of operations in one machine tool.

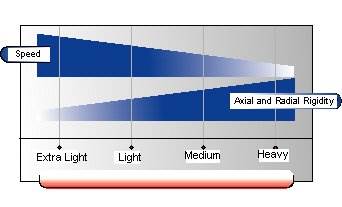

Read MoreBearing Enhancements - How New Technology Can Impact Machine Performance

By paying attention to such details as bearing selection and grease delivery systems, moldmakers may be able to increase machining speeds by up to 20 percent.

Read MorePre-hardened Tool Steel Saves Time and Money

Using NAK 55 standard mold bases allows moldmakers to focus on crucial core and cavity work.

Read MoreMold Base Advancements Set a New Standard

Further standardization and more options allow moldmakers to concentrate on fine detail.

Read MoreMotivating Your Environment Enables Earnings

A company is only as strong as its employees. Understanding their needs and concerns can be positive for both the working environment as well as company profits.

Read More