MMT Blog

SPI Machinery, Molders & Moldmakers Divisions

The missing link in the SPI, the MoldMakers Division strives to educate and keep the moldmaking industry competitive.

Read MorePart 2: New Tool Concepts for Machining Dies and Molds

The use of multifunction inserts is a significant geometrical development - making it possible to machine various operations with a single insert.

Read MorePM Mold: Rising to the Challenge

This moldmaker's success in tough economic times lies in art-to-part capabilities and diverse mold offerings.

Read MoreHow to Work Better, Faster and Cheaper

While moldmakers may have difficulty competing with foreign markets on cheap labor, they can compete by finding new ways to build molds faster and cheaper with high-quality results.

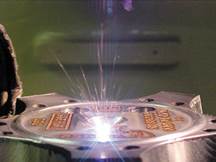

Read MoreLaser Engraving Enhances Mold Design

Consideration should always be given to the optimum cost/quality relationship when choosing laser engraving.

Read MoreCanadian Association of Moldmakers

Committed to advancing the industry, CAMM invests in apprenticeship programs and works to increase industry awareness to the general public.

Read MoreNew Tool Concepts for Machining Dies and Molds

The development and introduction of new insert and tool geometries for machining dies, molds and housing is an ongoing process - improving performance, tool life, surface quality and economy.

Read MoreHydrogen Embrittlement: How Small Details Can Have Large Effects

Knowing the facts about hydrogen embrittlement from the beginning will save both time and money down the road.

Read MoreMiniature Tool & Die: Good Things Come in Small Packages

Micro molding and micro EDM'ing help a moldmaker fine-tune its niche and double sales in a year's time.

Read MoreSetting Up Shop in Mexico

Moldmakers and suppliers weigh in on the pros and cons of establishing satellite operations south of the border.

Read MoreHow to Control Excessive Tool Wear

By calculating feeds and speeds properly, moldmakers can reduce tooling costs, have less machine downtime and see less scrap due to worn tools.

Read More7 Key Advantages of Hot Runner Systems

While both hot runner and cold runner systems have their benefits, for design flexibility as well as reduced cycle times and costs, hot runner systems will probably be the better choice.

Read More