Where Will They Come From?

In 2015, the Pellet to Part series focused on providing a better understanding of the plastics molding process by reviewing the physics behind how a plastic pellet becomes an injection-molded part. This year, the series will suggest unique ways to transfer technology to the current talent pool and examine where we might find the next generation of moldmakers and molders.

Typically, “they” refers to any employee joining the moldmaking and plastic injection molding workforce with or without the necessary experience, education or skills. In the plastics industry, this includes process engineers; program managers; moldmakers; apprentices; operators; material handlers; support staff; and logistics, quality control and IT personnel.

A job in manufacturing comes with some basic requirements including a high school diploma or GED, passing random drug screenings, and maintaining reliable transportation to and from work. To most, these aren’t major challenges, but to many others they are. At the other end of the spectrum, there is a real need for a highly skilled and educated manufacturing workforce, and this need will only increase as manufacturing technologies advance. Putting a sign in the front yard, running a help wanted ad in the local paper, and using online job posting boards, recruiters and word of mouth can be productive, but these strategies are not meeting the current pace.

During an “up” economy, the demand for candidates with experience, soft skills and work ethic to fill these positions is high, but traditional resources for reaching and securing such candidates are not adequate. Let’s take a look at the where and how of finding, employing, training and retaining these people as valued employees with some creative, nontraditional suggestions for securing a reliable workforce.

Ask Yourself

Where will you find your next employee? Once you employ him or her, how will you educate, mentor, retain and grow that person in your organization with the intent of employing him or her over a longer period of time? Then ask yourself, “Why can’t I be the next great person in the plastics industry? Why can’t I employ change?”

I personally have grown tired of rhetoric like “We can’t do that” or “Yeah, but they have low-cost labor, and their government subsidizes steel.” What I want to hear is, “How can we do that?” We can by developing innovative high school programs, accredited state and federal apprenticeship programs, formal college plastics programs, and in-house training/mentoring programs. There are people and programs that use nontraditional means to attract and retain next-generation workers, including David Cieslica, the president and managing director of HotSet America in Swainsboro, Georgia. He is working with the Great Promise Partnership (GPP), which aims to use education to help break the cycle of poverty. As a 501(c)(3) organization, GPP is affiliated with the Georgia Department of Economic Development, Workforce Division. In partnership with numerous community and business leaders, Georgia’s Department of Community Affairs developed GPP to help at-risk students complete their high school education while also gaining real-world job skills. The organization forms public/private partnerships in communities across Georgia.

Through GPP, I discovered a few specific organizations that are doing innovative things to address these common next-generation workforce questions and challenges. They are not

final solutions by any means, but they are blueprints for how

to do things differently to yield success in education and employment. Both of these programs target “at-risk” students:

1. 12 for Life

Developed in 2007 alongside the Carroll County Georgia schools, 12 for Life is a co-operative education program supported by Southwire Company, a manufacturer of wire and cable used in the distribution and transmission of electricity. The 12 for Life program falls in line with the company’s mission of empowering its customers, employees and communities, providing co-ops with real-life experience, a paycheck and an education.

Southwire’s “bricks-and-mortar” approach to the issue is impressive. A factory with upwards of a few hundred student employees who are working and going to school is innovative. 12 for Life is not to be confused with a vocational technical program or apprenticeship program, however. It is unique in the mentorship aspect of it, addressing individual challenges and working through them with the student/employee.

Specifically, 12 for Life provides a combination of both classroom time and time on the manufacturing plant floor, but it also develops the participant’s “soft skills” through direct mentorship. This not only enables the students to earn high school diplomas, but also addresses their longer-term plans for taking advantage of workforce, education and/or military opportunities. Students spend part of the day at school and part of the day at a job location. The employer partners with the community team to provide life skills training along with mentoring and tutorial help.

2. Great Promise Partnership Workplace

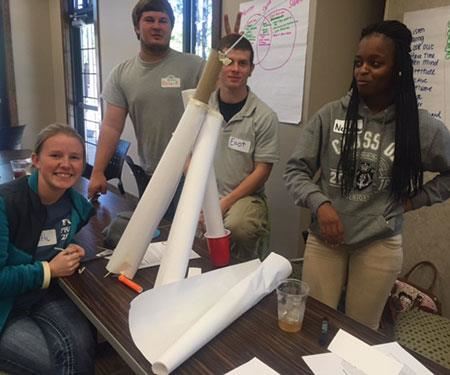

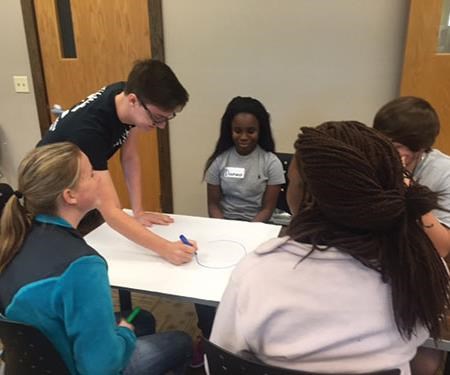

The Great Promise Partnership Workplace program is closely related to the 12 for Life program, but it includes an outreach component, with the intention that it be adopted by many. GPP Workplace focuses on preparing at-risk students that are too young or not yet ready for employment by regularly engaging them in life skills training, leadership development and decision-making processes. Bi-weekly classes on life and career skills, regular discussions of career and post-secondary education possibilities, and interaction with community and state leaders are all part of the program.

All GPP students also have the opportunity to participate in Leadership Adventure Weekends (LAW), which are facilitated by

specially trained instructors at University of Georgia 4-H Centers. These weekends also focus on college and career preparation, leadership skills development, team-building and the empowerment of individual students. They also provide an opportunity for these at-risk students to just be kids and have fun.

Identification of students for these programs is a collaborative effort between the employer and school system personnel, with GPP facilitation. Students complete an application and go through a series of interviews. Pay raises are earned based on academic progress at school, attendance and behavior at school and work, and job performance. Students that qualify have the opportunity to earn high school credit through school systems’ work-based learning programs.

These are just two organizations currently instilling a sense of value and self-worth in people; investing time and effort in high school or younger kids who are ‘at risk’ of not graduating by supporting them through high school graduation; providing real-world work experience; teaching young people how to be good employees and encouraging kids to continue their education beyond high school. They are employing the change this industry needs to create its own future workforce. What will you do?

Related Content

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreHow to Foster Innovation Through a Culture of Education, Mentoring

Dynamic Tool Corp. shares its strategy for building a team with the right attitude and aptitude to deliver innovation that meets customer expectations.

Read MoreCross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreRead Next

Getting You to Think in Plastic First

The next step is to take the lessons learned from this series over the past year and figure out how to impart them to the future moldmaking/molding workforce.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More