Where Is 3D Printing Headed?

You really can't watch the news or browse the internet without finding some exciting story on 3D printing, and according to 2013 Wohlers Report the use of 3D printing for final part production continues an impressive 10-year growth trend.

You really can't watch the news or browse the internet without finding some exciting story on 3D printing, and according to the 2013 Wohlers Report the use of 3D printing for final part production continues an impressive 10-year growth trend. And you can always read our take on applications and developments in AM via our quarterly Additive Manufacturing Supplement.

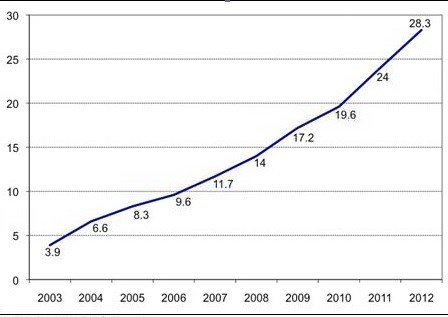

According to Wohlers Report 2013, final part production rose to 28.3% of the $2.2 billion spent last year on 3D printing products and services worldwide. In 2003, it represented only 3.9% of revenues, as shown in the chart.

The use of 3D printing, also referred to as additive manufacturing, for final part production is growing in several diverse market segments. They include metal copings for dental crowns and bridges, orthopedic implants, and jewelry. The aerospace industry is also an important market for the production of 3D-printed parts. Boeing uses additive manufacturing extensively to produce environmental control system ducting for directing the flow of air on military and commercial aircraft. GE Aviation announced that it will use 3D-printed fuel nozzles on its next-generation LEAP engine. The company plans to 3D print about 40,000 nozzles annually for its aircraft engines in the coming years.

The production of parts for final products is expected to far surpass prototyping applications for 3D-printed parts, according to Tim Caffrey, senior consultant at Wohlers Associates. This is because the ratio of prototypes to production parts is often 1:1,000 or greater. “The money is in manufacturing, not prototyping,” said Caffrey. “The opportunity for more commercial production activity from additive manufacturing is immense.”

Caffrey is a principal author of Wohlers Report 2013, the definitive state of the industry report for additive manufacturing and 3D printing. Many have referred to it as the “bible” in additive manufacturing. The annual report covers all aspects of 3D printing, including its history, applications, processes, manufacturers, and materials. It documents important developments, covers R&D and collaboration activities in government, academia, and industry, and summarizes the state of the industry in countries around the world. The 2013 edition marks the report’s 18th consecutive year of publication.

The 3D printing industry is expected to continue strong double-digit growth over the next several years. In four years, Wohlers Associates believes that the sale of 3D printing products and services will approach $6 billion worldwide. By 2021, Wohlers Associates forecasts the industry to reach $10.8 billion. It took the 3D printing industry 20 years to reach $1 billion in size. In five additional years, the industry generated its second $1 billion. It is expected to double again, to $4 billion, in 2015.

Wohlers Associates is an independent consulting firm providing technical, marketing, and strategic advice on new developments and trends in rapid product development and additive manufacturing.

Wohlers Report 2013 is a 297-page industry study is packed with up-to-date and practical information. It includes 35 charts and graphs, 55 tables, and 200 photographs and illustrations. The report was created with support from 74 service providers, 31 system manufacturers, and the valuable contributions of 75 co-authors in 21 countries.

Photo courtesy of Ford.

Read Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More