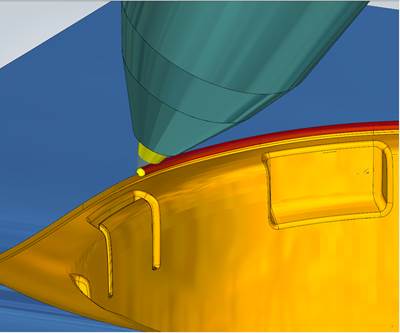

A bottle mold with high-performance material added to the edges using a hybrid CNC machine. Photo Credit, all images: Hybrid Manufacturing Technologies

With the advancements in CNC machining and EDM over the last decades, mold builders can produce molds and tooling with higher tolerances in shorter amounts of time than ever before. While this approach is optimized to address routine needs, there continue to be growing opportunities for new approaches.

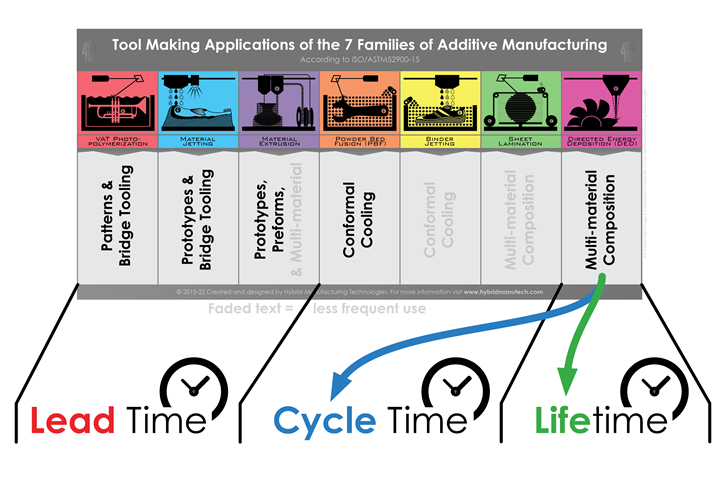

Although many mold builders have heard of additive manufacturing (AM, also known as 3D printing), the reasons to adopt it have not yet become entirely clear or compelling. Too often, the value proposition of AM gets clouded because of the many techniques and choices available. After all, with AM, it is possible to address a wide range of moldmaking needs from printing entire molds or inserts (often with powder bed fusion/PBF or vat photopolymerization) to localized repair or hardface welding of mold surfaces (often with directed energy deposition/DED). However, in moldmaking, these use cases ultimately translate into improvements in time, time and time—specifically improvements to lead time, cycle time and lifetime.

Unfortunately, no single AM technique achieves all of the benefits touted under the broad AM technology banner. For that reason, matching the desired application with the optimal AM technique is a critical step to use AM successfully. Figure 1 illustrates the seven families of AM (per ISO/ASTM 52900:2015) mapped to applications and the resulting time savings (click here for a more detailed infographic on the seven AM families).

Tooling Lead Time

Some AM techniques—most frequently vat photopolymerization, material jetting and material extrusion—can be used to produce tooling with shorter lead times than conventional moldmaking. One factor that can help AM printing workflows to be faster is eliminating the lead time for billet supply. The commonality of feedstock within each AM process means that one size/format of feedstock is used for every size of printed molds (or parts), making it easy to keep in stock (in contrast to the different billet sizes needed for optimizing time and cost when machining). Also, programming and operating 3D printers can be simpler and faster than using subtractive CAM/CNC.

Finally, the geometry freedoms afforded by some AM techniques can avoid spark erosion, thus reducing moldmaking steps. Producing short-run bridge tooling such as inserts printed using polymer—especially filled polymers—is becoming more practical and widespread. Commonly, short-run polymer tooling is used in the “as-printed” state without further machining. Hybrid CNC machines that achieve metal printing and finish machining in the same setup (machining fully dense metal or green bound metal parts that need furnace sintering) can also accelerate the moldmaking timeline.

Although many mold and tool builders’ needs are still best addressed using subtractive machining and spark erosion, AM is making inroads to deliver significant timesaving.

Molding Cycle Time

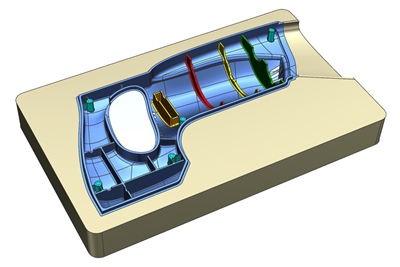

While the design rules for molding surfaces, including draft angles, venting, etc., have been refined to a science over the last several decades, the way that the temperature of a mold is controlled is undergoing re-evaluation, in part thanks to AM. Two different approaches to reducing cycle time through temperature control are facilitated by AM: (1) change to the shape of cooling channels and (2) improving heat transfer with multi-material molds.

The first new trend is a shift away from the exclusive use of straight drillings toward conformal cooling channels printed using PBF. Conformal channels follow the form of the molding surface more closely, so they achieve a more even temperature throughout the mold. This has been demonstrated to reduce cycle times by as much as 15-30%. For longer runs, cycle time savings can add up quickly, acting as a strong motivator to invest in molds with conformal cooling channels. Molds with conformal cooling channels are printed and then the mold surfaces are finish machined (the same as a traditional mold).

The second trend is using multiple materials in a mold as achieved using DED. For example, the bulk of the mold can be made using a thermally conductive material (such as bronze) and a harder material at the molding surfaces.

Unfortunately, no single AM technique achieves all of the benefits touted under the broad AM technology banner. For that reason, matching the desired application with the optimal AM technique is a critical step to use AM successfully.

Mold Lifetime

DED can add high-performance materials to molds. This is known as hardface welding, where an additional material is applied to the edges or other critical surfaces of a mold that are prone to wear and damage. This spares the use of cost-prohibitive, exotic materials to make the entire mold, while enabling it to last much longer than typical tool steel. The lifetime of a mold can often be doubled or tripled using this approach.

Note: In DED and PBF, the metal fused during printing typically has a finer grain structure and higher hardness, which naturally imparts an above-average lifetime to molds made by these methods.

An example of mold hardfacing can be seen in Moldmaking Technology’s April 2021 “Use Hybrid AM to Produce Longer-Lasting Multi-Material Molds.” In addition to reinforcing the mold for its initial lifetime, DED can repair and remanufacture the mold to be fit for additional lifecycles. In both hardface welding and remanufacturing, machining is typically used to finish the tooling.

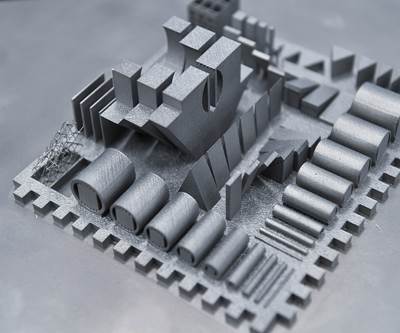

Nearly all of the approaches for printing metal still rely on machining to finish surfaces. However, recent advancements have resulted in “hybrid machines” that combine AM techniques, including PBF, binder jetting, material extrusion and most frequently, DED with machining. Such hybrid machines can yield additional time savings for some moldmaking process chains.

AM offers some new options to augment traditional moldmaking equipment. However, to evaluate their utility, it is essential to get very specific about the exact AM technique being considered and the sought-after benefits corresponding to the respective reduction in lead time, cycle time or lifetime.

Related Content

3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreProducts and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreHow to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

Read MoreRead Next

Five Key Aspects of a Basic Multi-Axis AM Programming Workflow and CAD/CAM/AM Tools

CAD, CAM and AM tools in the same software package and user interface ease programming for mold builders employing additive manufacturing operations.

Read MoreHow to Select the Right Programming CAM Software for Directed Energy Deposition in Mold Repair and Modification

Selecting the right programming CAM software improves the use of directed energy deposition to repair and modify tooling.

Read MoreBuilding Confidence in AM for Tooling

New potential for tooling applications is reached with custom-designed materials for additive manufacturing.

Read More