The Effects of Hardware Developments on CAM

Mold manufacturers can experience four common benefits from advancements in system hardware.

With most new releases of CAM software, the developer will focus on the latest machining strategies that are available in the system. Over the past two years, however, promotional material for new versions has been full of claims about the ability to support the latest hardware developments, such as background processing and multi-threading. This article will explain why these developments are important and the benefits that they can give to the user.

The key change in computer hardware has been the move from single-processor computers to multi-processor equipment. After many years of steadily increasing processor speeds, there has been a step change in processing power through the much wider introduction of multi-processor equipment. Many laptops for home use now come with dual processors, while computers for commercial use will often include four, eight or even more processors.

1. Benefits of Multiple Processors

There are two main benefits from multi-processor computers—background processing and parallel processing (also called multi-threading).

Background processing allows the user to prepare, simulate or edit one toolpath in the foreground, while simultaneously calculating other toolpaths in the background. This means that the user no longer has to wait for each calculation to be completed before work can start on the next operation. For example, the user can be setting the parameters needed to machine one area of a part, while toolpaths are being calculated in the background for a second area using a different strategy.

Productivity is also increased because the computer can continue with a series of calculations during the user’s breaks. Calculations can be queued in the system and the software will automatically start the next operation as soon as each toolpath is completed.

With parallel processing, the computer can perform different parts of a single complex calculation at the same time by dividing the processing of this operation over all of the processors. This spreading the load between multiple processors allows calculation times to be reduced significantly.

The extent of the savings will depend on the size and complexity of the part being machined, and on the programming strategies being used. Recent tests have indicated that a dual core computer will perform faster machining calculations in around 55 percent of the time taken by a single core machine. A quad core machine will complete the calculation in around 35 percent of the time and an eight core machine in around 25 percent of the time.

The ultimate benefit comes from applying both of these technologies at the same time, with parallel processing being used for both the foreground and background operations.

2. Coping with Complexity

There are, of course, obvious benefits in being able to reduce calculation times and waiting times. User productivity can be increased significantly, reducing any downtime where machine tools are waiting for NC data and therefore minimizing leadtimes. These benefits are most important for companies that are using the latest generation of highly-sophisticated machine tools, like five-axis machines and mill-turn equipment.

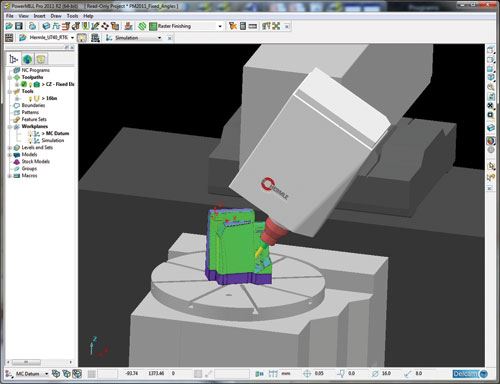

The problem with this more advanced equipment is that calculating toolpaths for their operation is more complicated than for simple lathes or three-axis machines. Not only are there more options to consider, but the software will need to undertake more comprehensive checking to ensure that collisions will not occur.

For example, many CAM systems now include some sort of automatic collision avoidance during five-axis machining. The software will change the tool axis automatically when collisions might occur, tilting the cutter away from the obstacle by the specified tolerance and then returning the cutting angle to the value set for the overall toolpath once the obstacle has been cleared.

More sophisticated systems will even incorporate a look-ahead distance as part of this capability in order to ensure a smooth transition when tool-axis changes are required. This all involves extra calculation and checking, making the extra speed of modern hardware an even more important benefit.

3. Stock Models

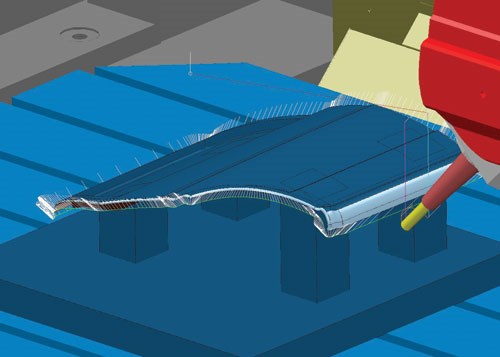

Another intensive computation involves the production of stock models (models of the material still remaining on the part) during the machining process. The models can be used by the system to ensure that the cutter is never asked to remove more material than it can safely cut. At the same time, they also ensure that toolpaths are not produced where there is no material remaining, so any time spent cutting air is minimized.

The ability to optimize tool loading with stock models will help overcome a constant conflict for programmers. On the one hand, they want to maximize productivity by setting feedrates as fast as their machines will allow, but on the other hand, they need to ensure safe speeds that will not break the tool.

4. Simulation

As mentioned previously, background processing allows simulations to be undertaken simultaneously with other calculations. This aspect of programming has also benefited from the better quality of the graphics that can be provided in the latest computer hardware. These improvements have made it possible for software developers to generate accurate, three-dimensional models of a wide range of machine tools and to then simulate the complete machining process. It is even possible to give an indication of the surface quality of the part.

Being able to prove out the program on the computer gives a very high confidence that it will work successfully on the machine tool. It is, of course, much cheaper to find mistakes on the computer than on the machine tool, where there is a risk of scrapping the mold or part, breaking the cutter or damaging the machine.

Summary

The latest hardware developments can help CAM users to be more productive. An investment of a few thousand dollars in a better computer can give huge benefits to mold manufacturers, especially those using more sophisticated machine tools to produce large or complex molds and parts. With those machines costing hundreds of thousands of dollars, it seems very short-sighted not to provide the best supporting systems for a small additional investment.

Related Content

How to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

Read MoreHow to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreRead Next

Software Enhances Advancing Technologies

CAD/CAM’s improved features and new capabilities—combined with the latest in technologies like high speed and five-axis machining, new cutting tools and 3-D technologies—allow moldmakers to achieve the highest quality in the shortest time.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)