This is a hardface-welded mold for making glass bottles made by Ross International. The hard edges were deposited and finished in minutes via a single setup using an AMBIT hybrid CNC machine. All photo credit: Ross International and Hybrid Manufacturing Technologies.

We are all still looking for the perfect material for molds and dies. You know, the one that is as easy to shape as butter during moldmaking, yet performs like hardened tool steel for molding parts, all while drawing heat out quickly to minimize cycle time. However, even with significant advancements in heat-treatable tool steels and innovative use of inserts, there is still tension between the material characteristics that we desire for moldmaking, and those needed for molding performance. Often, these contradicting demands oblige us to spend more on making molds than may be required, just to be sure that they will last long enough, or so they can handle unanticipated part shrinkage with minimal modification.

Two Materials Can Be Better Than One

Hybrid additive CNC machines open a new, more practical path for moldmakers to leverage the characteristics of two or more metals together in order to reduce the tension between moldmaking and molding performance demands. The process for adding another metal to edges and faces is often referred to as “hardface welding” or “mold enhancement” by Directed Energy Deposition (DED) additive manufacturing (AM).

Adding material enables the use of a relatively easy-to-machine material for most of the mold, and then only requires adding hard material where it is needed most. Using multiple materials also allows the tailoring of additional mold properties. Hardface welding, and even mold modification, can be conveniently achieved using a laser-based DED method inside CNC machines, a combination known as hybrid manufacturing.

Hardface Welding

Hardface welding onto mold edges or surfaces using a high-performance material is a well-established approach for making long-lasting, high-performance molds. Hardface welding means adding additional metal to reinforce or build up selected areas of a mold. The added material can provide increased hardness, durability or corrosion resistance. It is also a step beyond hardening by heat treatment or nitriding because it deposits an additional material. Only a few minutes of depositing a more exotic material in selected locations can often dramatically extend the service life of a mold.

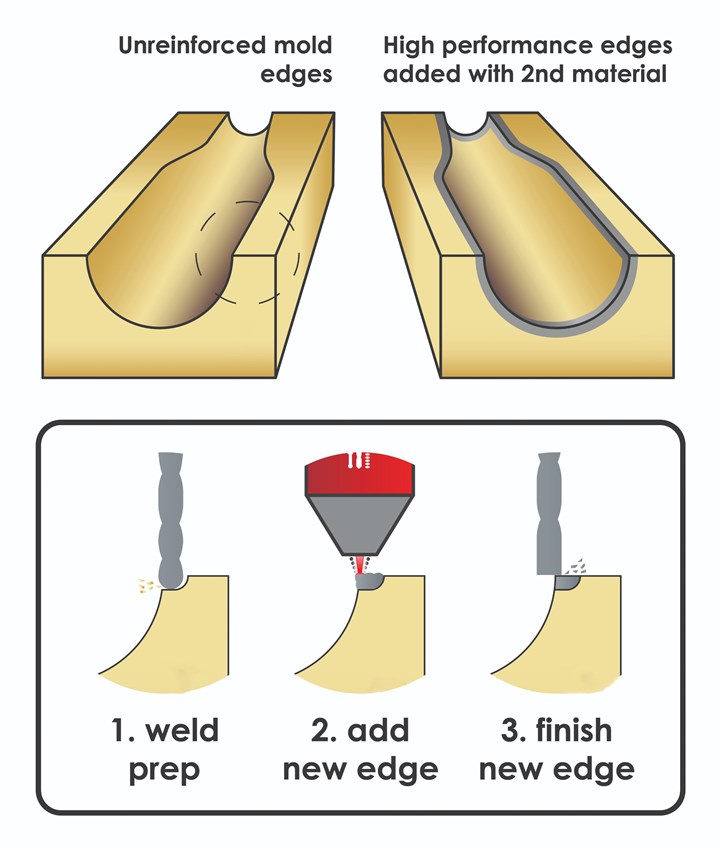

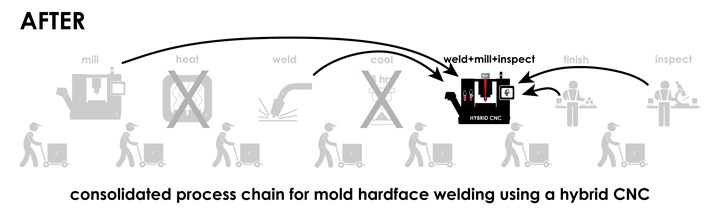

Steps to hardface weld a mold using a high-performance material to produce long-lasting, high-performance molds.

Here is how to hardface weld a mold:

- Make sure the edges and surfaces where metal will be deposited are cut undersized.

- Use a metal deposition head to add metal to these areas until they are slightly oversized.

- Machine or grind to finish the welded metal to its final shape and to blend with the rest of the mold.

Historically, shops performed these steps separately. So, despite the widely acknowledged benefits of hardface welding, routing parts through the many production steps for hardface welding molds was often a chaotic journey and required highly-skilled or supervised employees to do it well. Even by leveraging the automation of CNC and DED independently, this can be logistically daunting and is too seldom attempted.

Innovations in hybrid manufacturing over the last five years, however, have proven transformative for hardface welding of molds. By enabling DED together with machining, all steps can now be achieved in the same setup along with milling the rest of the mold. With hybrid CNCs, hardface-welded molds can often be faster and easier to produce than molds with hardened inserts that require separate spark erosion and hard machining setups. One key consideration for this comparison is whether the mold geometry allows deposition nozzles to access areas where a new metal is desired.

Hardface Welding for Glass Bottle Molds

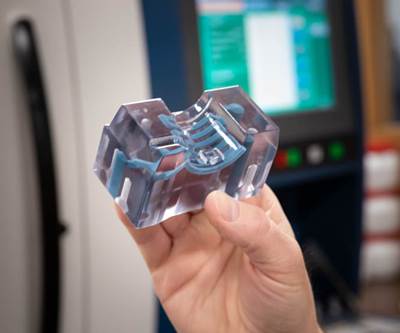

The extreme performance requirements of glass bottle molds vividly illustrate the benefits of using two metals in a mold. An example of a bottle mold with hardfaced edges is shown below. Notice the gray edges of this otherwise bronze mold for making glass bottles. The edge is made from a nickel-based superalloy and is the only area of the mold receiving printed metal. The rest of the mold is cast and milled. Here's why.

The additive step on this glass bottle mold is only needed at the edges, and it brings tremendous value.

A big driver for the cost of bottles is the speed with which the glass bottles can cool down enough to be self-supporting and removed from the mold to be annealed. Typically, glass bottle molds are made of gray cast iron because this material handles the abrasive molten glass well. The problem is that gray cast iron does not get rid of heat quickly, limiting bottle production speeds. For this reason, manufacturers may switch to bronze, which removes the heat quicker and allows the shop to run the line faster, bringing down the cost of each bottle.

Although the transition to bronze molds seems like the right choice, bronze is relatively soft, meaning the edges won't survive as long. Plus, if the edges become damaged, the repair is not easy. To compensate for this, shops have used conventional hardface welding (adding nickel-based superalloys) along the edges for decades. Before hybrid manufacturing, this meant committing to an extended mold manufacturing process—rough milling, preheating for conventional arc-based welding to prevent cracking, welding and cooling for eight hours to achieve dimensional stability before final milling.

In this case, the very characteristic a shop wants in mold performance—the ability to draw heat out—adds complications during moldmaking. A pre-heated bronze mold won't stay hot enough for long enough to do all the necessary welding conventionally. This requires repetition of steps, as shown in the “before” illustration above. A portion of the welding occurs, then a portion of that weld is milled away, and then the mold is reheated to repeat these process steps, resulting in numerous steps and setups.

Open-architecture hybrid machines allow mold builders to hardface weld a mold's edges and surfaces with far higher efficiencies than a traditional job shop workflow that uses separate setups.

Apply and Simplify with Additive

Now let's examine this process with new eyes and think about additive as a solution by using it within a hybrid CNC architecture. First, replace conventional arc welding with laser-based DED, which skips the need for preheating and cool-down cycles. Next, take the DED process and place it into the milling machines. Now you can bring all required processes to these parts in a single setup. This eliminates every transfer step until the finished part leaves the machine.

This approach demonstrates a clear before-and-after, yielding a tremendous boost to efficiency by consolidating those processes onto hybrid all-in-one CNC machines. This approach also reduces even the shortest mold production time from nearly four days to less than 40 minutes and cut costs in half for each part.

These advantages motivated Moldes Medellin (a Ross International subsidiary, Antioquia, Colombia) to convert mold production to a hybrid CNC approach starting four years ago. The company now make thousands of molds per year using hybrid CNC machines.

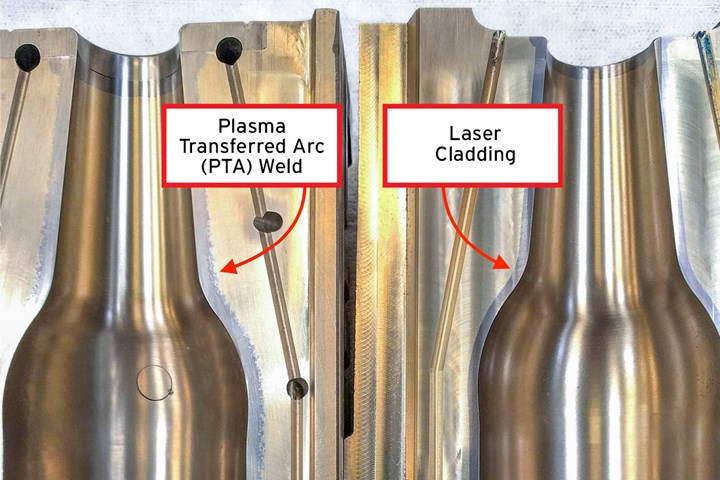

Look at the difference between a plasma-transferred arc (PTA) weld and a weld via a laser-based, hybrid all-in-one machine (laser cladding). A ragged weld indicates the amount of heat input and metal mixed in the dilution area, creating a large heat-affected zone. The laser-based weld shows a straight line with smaller dilution and heat-affected zones, which lengthens mold life.

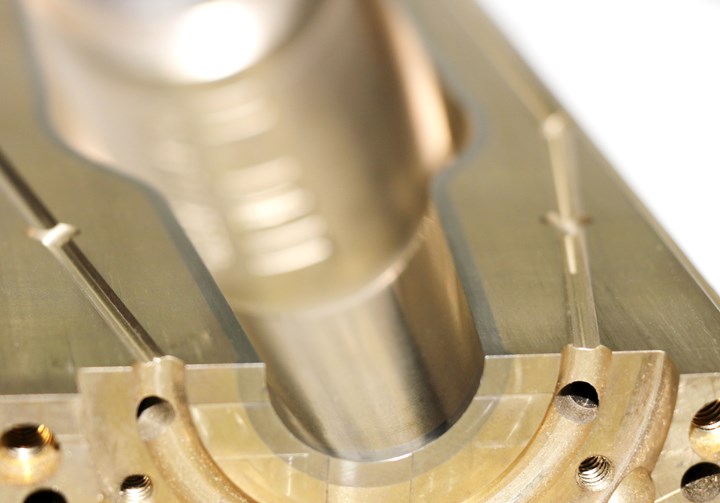

Applying laser-based metal deposition on a milling machine brings multiple processes together to make parts, like this mold component, and eliminates transfers between production steps.

The benefits of a hybrid process are multi-faceted. Molds can be produced with higher quality and speed. When it comes to managing parts, this approach yields a drop in work in process. Plus, you reduce capital investment, as you can unify on CNC machines, enabling a simplified workflow where line balancing fades away, allowing a shop to focus on merely producing. Energy savings during mold creation and follow-on bottle making can be significant. Lastly, with a single seat of CAD/CAM, one person can prepare tool paths for all of these processes via a single post-processor, simplifying the additive and subtractive finishing steps.

This streamlined method of producing molds from multiple metals bodes well for other moldmakers who have considered hardface welding previously and need more evidence or a more practical approach to justify its implementation.

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRead Next

Cutter Considerations for Hybrid Additive Manufacturing

Four tips for applying the right cutting tools in hybrid additive manufacturing.

Read MoreVIDEO: Custom Mold & Design Talks Hybrid Additive Manufacturing

Lester Jones, VP of Custom Mold & Design discusses the shop's use of its Matsuura Lumex Avance-25 hybrid AM machine for creating conformal-cooled inserts with MoldMaking Technology Editorial Director Christina Fuges.

Read MoreMold Builder Learns How to Use Hybrid AM to Build Conformal-Cooled Inserts

It is one thing to understand additive technology, but it is another to know when to invest, who to partner with and how to sell its value.

Read More