Photo Credit: (top left) Ingersoll Cutting Tools, (top right) Walter USA, (bottom left) Parlec/Techniks Tool Group and (bottom right) Tungaloy America.

In addition to the print-only cutting tool technology roundup released this month, MoldMaking Technology has compiled several newly released or optimized cutting tool products that aim to facilitate increased productivity, reliability and accuracy.

Indexable inserts, microtools, carbide milling cutters and a range of other offerings from well-acclaimed companies Ingersoll, Walter, Tungaloy, Guhring, Parlec and YG-1 can be viewed below.

MMT posts new products daily. For a more individualized search, take a look at the products sections housed under each designated category (e.g., machining, mold materials, etc.) or view them under “New Tech.”

Photo Credit: Ingersoll Cutting Tools.

The NuMaxHF line of new high-feed milling tools from Ingersoll Cutting Tools offers extreme ramping capabilities versus traditional high-feed milling tools, the company says. The thick, tangential insert features a diamond shape with a large inboard angle providing high feed rates and steep ramping angles.

Photo Credit: Ingersoll Cutting Tools

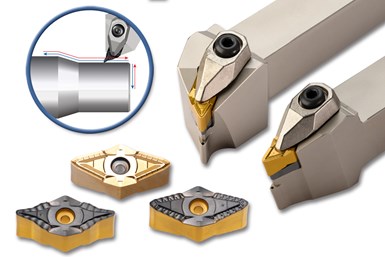

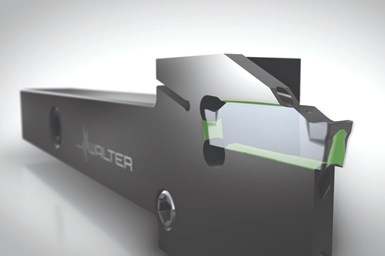

SuperTurnZ offered by Ingersoll Cutting Tools is an innovative system for multi-directional turning that utilizes the front and back cutting edge of a four-corner insert in a single tool. It reportedly represents a highly productive alternative to conventional turning.

Photo Credit: Ingersoll Cutting Tools

Ingersoll Cutting Tool’s CeraSFeed ceramic indexable high-feed line offers extreme roughing performance when milling heat-resistant super alloy (HRSA) materials. CeraSFeed features two double-sided indexable insert styles: LNXF09 and TNXN12. LNXF09 offers a 1.5-mm depth of cut and four cutting edges. TNXN12 offers a 2.5-mm depth of cut and six cutting edges.

Photo Credit: Sandvik Coromant

Sandvik Coromant has launched CoroCut QI, a range of internal and face grooving inserts designed for smaller diameters. Optimized to enable a lighter cutting action and reduced cutting forces, CoroCut QI is said to ensure high-process security, reliable grooving operations and precise chip evacuation, resulting in high surface quality grooves.

Cutting tool manufacturer Guhring reports that its microtool offerings, including the RF100 Micro-Driver, are an answer to the challenges imposed by the creation of small or miniature molds. The Micro-Diver carbide end mills deliver plunging, 60º ramping, and high-performance milling at tool diameters at or below 1/8".

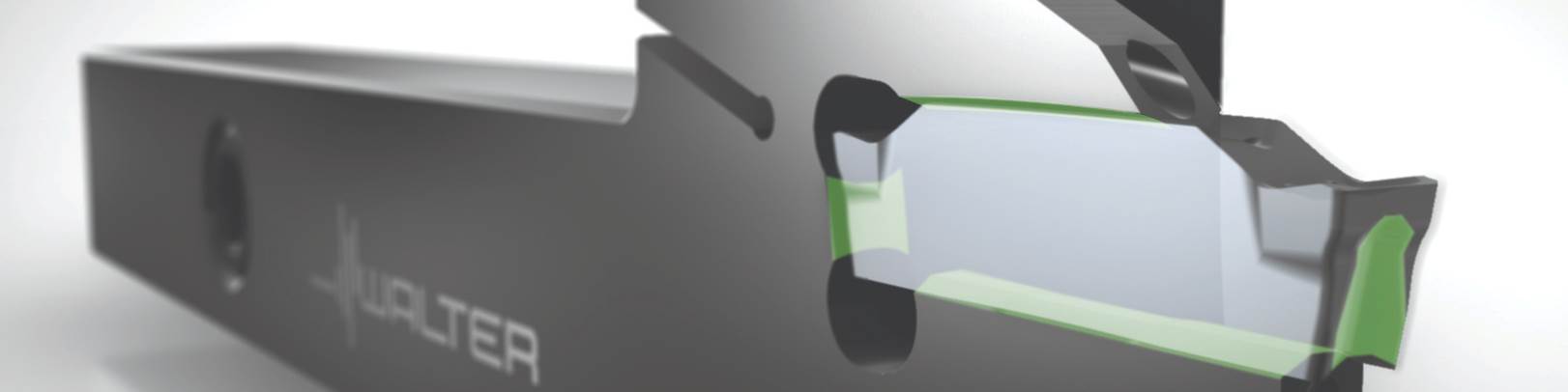

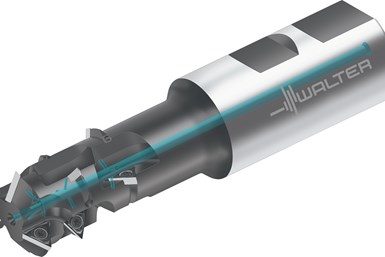

Walter USA has introduced the Xtra-tec XT M5004 octagon milling cutter, a versatile milling tool that combines productivity with stability. It can be used for face milling (roughing and finishing), ramping, pocket milling and circular interpolation, as well as chamfering and back chamfering of steel, stainless steels, cast iron, non-ferrous metals and materials with difficult cutting properties.

Walter USA presents two multi-tooth solid carbide face milling cutters, the MC128 Advance and the MD128 Supreme, for finishing and semi-finishing, with a secondary use for dynamic milling. These close-pitch cutters are said to produce excellent surfaces, with minimal burr formation on the component, primarily due to a 50° helix.

The Walter Cut DX18 double-edged grooving and parting off inserts with insert widths of 0.059-0.157" (1.5-4 mm) are the latest addition to Walter’s ever-expanding grooving product range. The patent-pending cutting insert is seated in the insert pocket with a prismatic design.

Walter USA has released two solid carbide milling cutters that successfully tackle titanium machining tasks: the MC377 Advance and the MD377 Supreme. The first is said to be a cost-effective tool for universal use in ISO materials S, M and P and the second specializes primarily in the aviation and aerospace industry. Both solid carbide milling cutters can handle roughing, finishing and semi-finishing as well as ramping, shoulder milling and plunging.

Walter’s launched T2710 indexable thread mill is reported to bring higher levels of productivity, reliability and quality to the machining of short threads. This multiple-row cutter is designed for high-cutting speeds and high feed per tooth, with an indexable insert boasting three cutting edges, all of which results in low cost per thread.

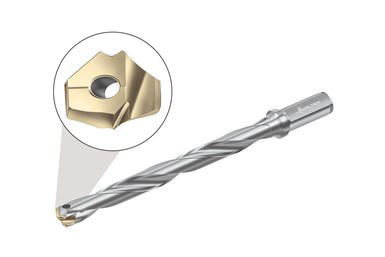

According to Walter USA, its P6006 insert for exchangeable-tip drills brings new levels of drilling efficiency to low carbon steels, structural steels and low alloy steels. Developed specifically for these materials, the insert features optimized geometry, with a sharp cutting edge and deep chip gash that leads to maximum process reliability and efficient chip breakage in low alloy or unalloyed steels.

Walter USA presents the TC420 Supreme thread for universal use. The HSS-E-PM thread former, with a high number of forming edges, produces high cutting speeds with up to 30% less torque, good surface finish and improved lubrication. The TC420 Supreme includes one configuration with chamfer form E (M5–M16) for blind-hole threads up to 3.5×DN, which uses a combination of chamfer form E with axial internal coolant and without lubrication grooves.

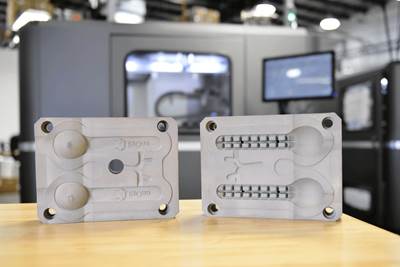

Parlec, a member of Techniks Tool Group, has released the P3 ER collet system, the first coated ER collet system according to the company. Parlec P3 ER collets feature an anti-friction coating on the 30° face of the collet that interfaces with the collet nut when tightening during tool setup.

Photo Credit: Parlec/Techniks Tool Group

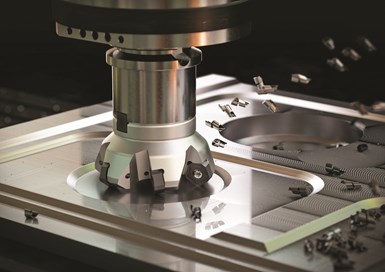

YG-1’s newly introduced FM10 PNMU face milling indexable inserts combine multi-corner face milling performance with high feed capabilities.

The FM10 PNMU inserts are designed to separate the cutting edge and the wiper, which results in ten true cutting edges.

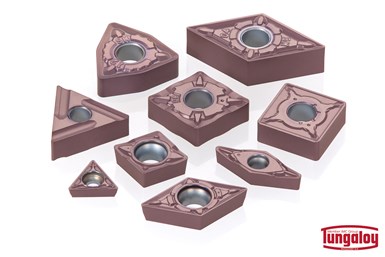

Photo Credit: Tungaloy America

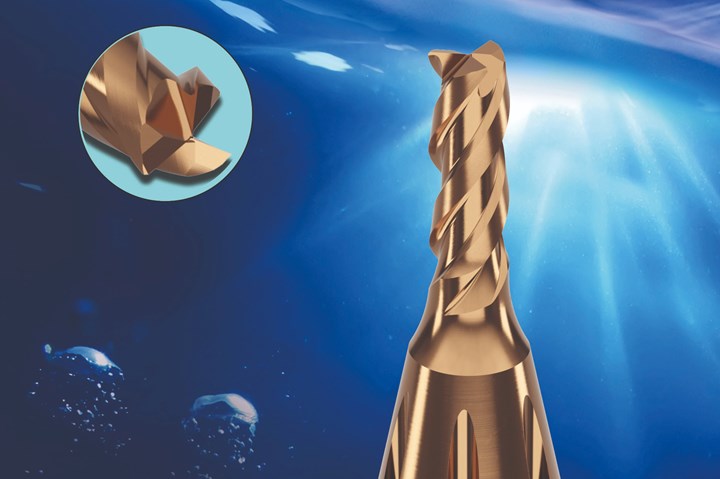

Tungaloy America’s AH6225 PVD grade insert for machining ISO-M stainless steels expands the application coverage from continuous to interrupted cuts in a broad range of cutting speeds, while maintaining tool life and reliability in stainless steel turning, from finishing to roughing.

Photo Credit: Tungaloy America

Tungaloy America has expanded its ISO-EcoTurn turning insert line by adding 63 inserts in new geometries.

ISO-EcoTurn inserts, while downsized for tool economy, incorporate the identical chipbreaker geometry and thickness of regular sized inserts to maintain the same cutting performance at a depth of cut up to 3.0 mm (0.12"). This expansion provides more cost-efficient solutions in steel turning applications, according to the company.

.png;maxWidth=300;quality=90)