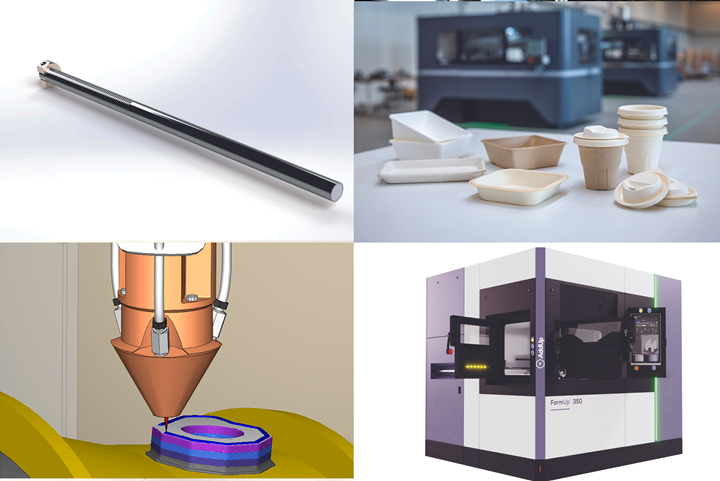

Photo Credit: (top left) Next Chapter Manufacturing, (top right) ExOne Co., (bottom left) CGTech and (bottom right) AddUp Inc.

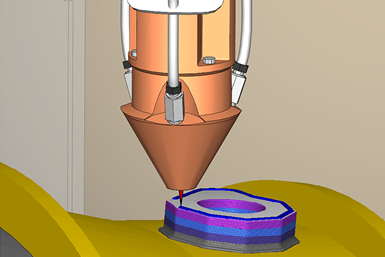

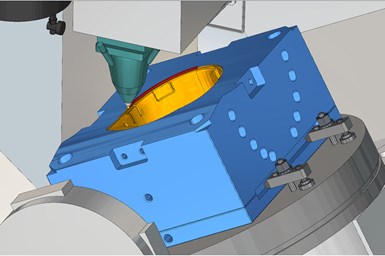

Additive manufacturing (AM) continues to build new opportunities for moldmakers, from saving on energy and material waste, decreasing cycle times, enhancing part reliability, eliminating design constraints and a host of other advantages.

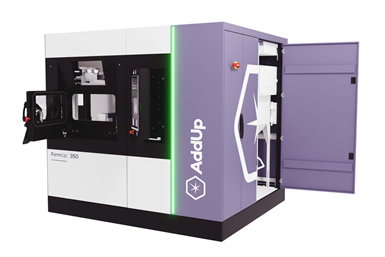

This trend is also being observed in the new software, equipment and materials offered to the industry, which is exemplified below, as well as in MoldMaking Technology’s upcoming December 2021 print/digital issue.

See what you might have missed below!

For additional information covering this topic, including case studies, a directory to primary AM-related suppliers and MMT Chats focused on this topic, take a look at the “Read Next” section.

Related Content

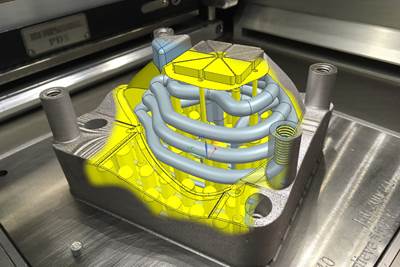

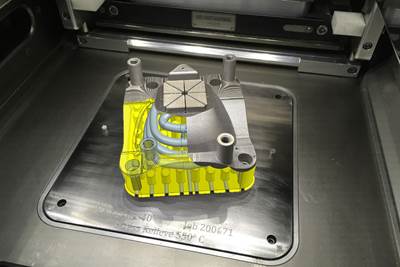

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read More3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

Read MoreMold Materials, 3D Printing Technologies for Next-Gen Moldmaking

As moldmaking advances, so too do the materials and processes involved in their efficient production, including these latest mold materials and 3D printing technologies.

Read More3D Printing Innovates Hot Runner Manifold Design

Metal 3D printing combined with a conventionally machined manifold block overcomes flow shadows on valve gates and offers faster color changes while providing closer system pitch centerlines between cavities.

Read MoreRead Next

Growing AM's Presence in Moldmaking

Advanced Michigan mold manufacturer advocates for additive manufacturing in moldmaking through collaboration and education.

Read More2021 Sourcing & Technology Guide: Additive Manufacturing

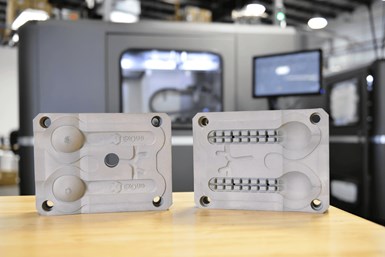

3D printing, or additive manufacturing, simplifies the moldmaking process by making mold inserts, mold components, end-use parts and ancillary equipment.

Read MoreHybrid Approach to Producing Mold Inserts Boosts Productivity and Profitability

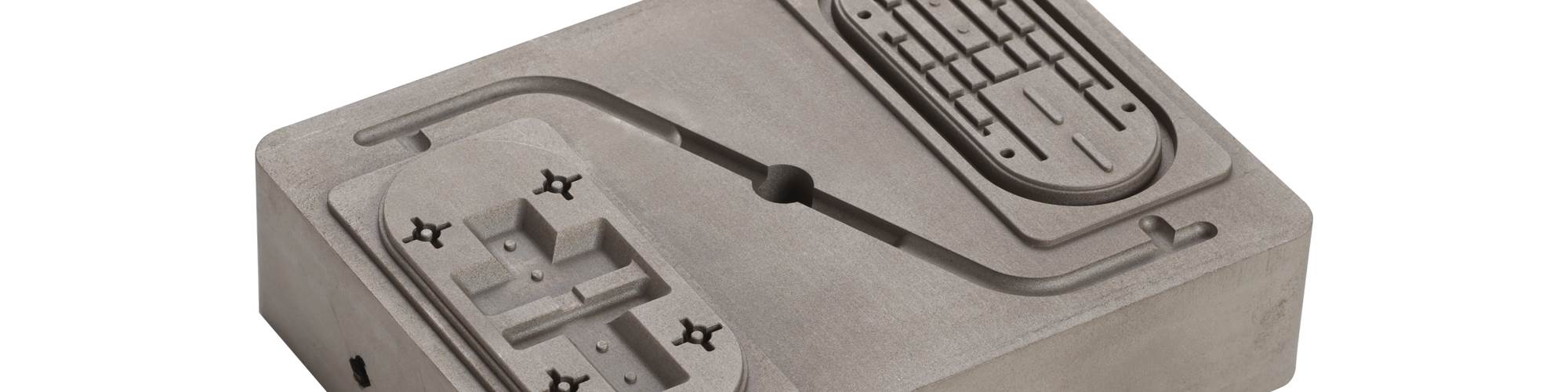

Mold inserts with additively produced cooling circuits eliminate design constraints, reduce the cost of complexity, improve part dimensions, decrease cycle time and speed time to market.

Read More