Solid Tool or Indexable Inserts? Why Not Both!

Kyocera SGS Precision Tools’ mill-turn demonstrations highlight varied tool choices and varied application knowledge.

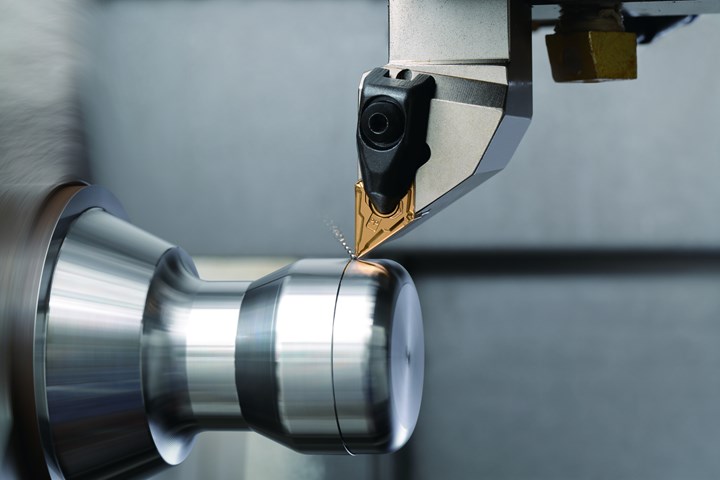

When does an application call for an indexable-insert cutting tool rather than solid carbide? With both tooling types on display in a shared space – an IMTS first for the jointly branded company – Kyocera SGS Precision Tools is likely to have the answer. In addition to standard milling and turning offerings, SGS’s solid line includes sweeping-geometry, circle-segment “barrel cutters” and coolant-through drills, while highlights of Kyocera’s indexables range from end and face mills to grooving, turning and drilling tools.

With application knowledge as broad as the jointly branded product offering, booth representatives also stand ready to show rather than tell. Live cutting demonstrations of both cutting tool types highlight where and why each stands out, while also showcasing the inherent flexibility of a mill-turn machine capable of milling and turning with both indexable or solid carbide tools.

Solid tools like the one cutting the blisk are the province of SGS, while indexable offerings like the turning tool are Kyocera’s specialty. Photo Credit: Kyocera SGS Precision Tools

Related Content

-

Cimatron 2025 Software Offers Benefits to Moldmakers

IMTS 2024: Cimatron announces the release of Cimatron 2025, a software version for advanced capabilities in design and manufacturing. The software enables improved modeling and electrode design for the moldmaking industry.

-

EOS Expands Materials Portfolio with Moldmakers in Mind

IMTS 2024: EOS North America highlights its latest industrial 3D printing solutions, including its upgraded portfolio of metal additive manufacturing (AM) solutions designed with industrial AM production in mind for industries such as moldmaking.

-

QFM Tooling System Offers Solutions for Mold and Die Industry

Cole Carbide Industries Inc. highlights the Quad Force Machining (QFM) tooling system from Millstar to provide maximum flexibility by way of its innovative hybrid geometry to provide a solution for diverse application challenges that face the mold and die industry.