Software Streamlines Electrode Production

This German manufacturer of custom graphite electrodes benefits from software that provides a seamless transition between specialized CAD and CAM functionality.

The Visi CAD/CAM solution from Vero Software has been instrumental in a German company becoming a sought-after business partner for producing custom graphite electrodes.

Located in upper Bavaria, Technologie Vertriebs und Beratungs GmbH (TVB) specializes in graphite electrodes and associated services, including design, 3D scanning, five-axis machining, and assembly on bracket and clamping systems. Graphite electrodes are more efficient than copper, requiring just 25 to 30 percent of the time to erode,” sasy Florian Rauchenberger, who is responsible for project management.

Approximately 70 customers hail from the tool and moldmaking sector, where increasing customization is driving more and more manufacturers to turn to specialists like TVB for electrode production, he says. “We produce an average of 12,000 to 15,000 electrodes a year in a variety of sizes. Compared with normal milling, projects involving electrodes move significantly faster. We often have to deliver up to 150 electrodes between just three and ten days after receiving the order.”

Visi has proven invaluable to keeping up with this ever-changing workload, he says. Working in conjunction with a sophisticated ERP solution, the software provides what he calls a “completely consistent CAD and CAM structure” which extends from the design through to the NC programming and up to the milling machines. “We chose VISI because the different modules are focused specifically on the requirements of the tool and mold-making industry. The system uses the same data models in the design as well as NC programming, and has the same self-explanatory operating philosophy across all areas.”

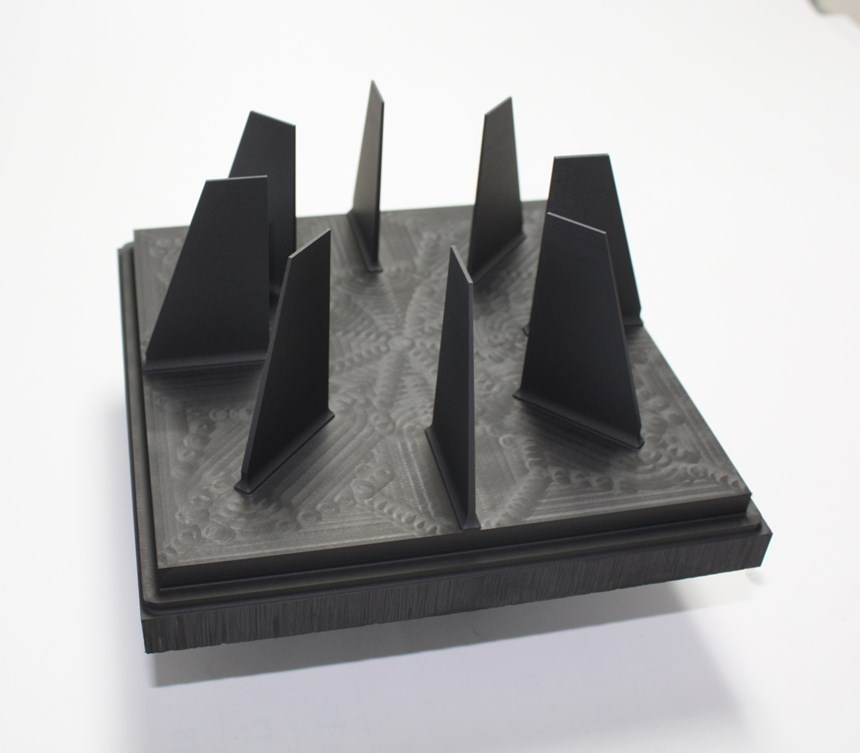

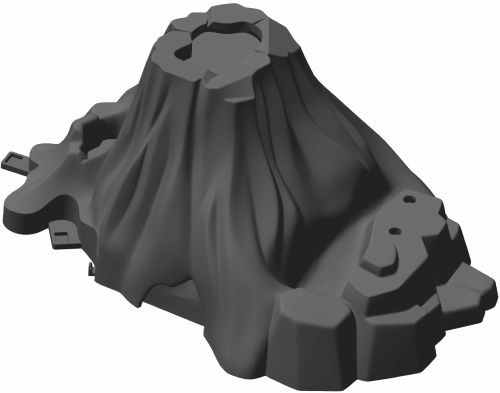

This common functionality is particularly important because TVB’s designers also generate the milling programs, he says. Moreover, the Visi Machining CAM module is installed on two workstations in the production department. Using Visi Electrode, staffers can simply extract electrodes from the tooling cavities. Areas targeted for erosion are detected independently, and electrode geometries are generated automatically with linear and tangent surface extensions. Moreover, the software offers CAM strategies developed specifically for graphite milling on the company’s E-Jet 550 modular, high speed cutting machines, which it developed in-house (see the image on the right for more information).

Rachenberger adds that the software even helps TVB win contracts in the first place. CAD data from the mold insert or the completed electrode design helps in various calculations such as which VDI (Verein Deutscher Ingenieure, the Society of German Engineers) surface should be achieved, which type of graphite should be used, the quantity of electrodes required, and the eroding schedule. With the contract won, the shop can set about addressing problem areas (high ribs or deep pockets), determining whether electrodes need to be fitted to brackets, and determining whether partial deliveries are required, among other considerations. If the customer doesn’t provide a complete electrode design, the shop uses Visi Modeling to extract the data and position the electrodes in the mold insert.

After programming, VISI Machining generates a tooling sheet which documents information for the machine operator such as tooling, speeds, feed rates and running times. The electrodes are measured using a CMM machine once milling has finished, and VISI Electrode generates documentation for each individual electrode, which is used by the eroder later.

“When a customer tells us they need a specific electrode in just two days, we have to make sure we can adapt our processes and deliver what they need,” Rauchenberger concludes. “Thanks to the suite of VISI modules, we can respond even quicker and more flexibly to special requirements, which benefits tool- and mold-making customers who are under considerable pressure to achieve increasingly shorter production times.”

Related Content

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More