SLIDESHOW: Technology Showcase, Inspection and Measurement

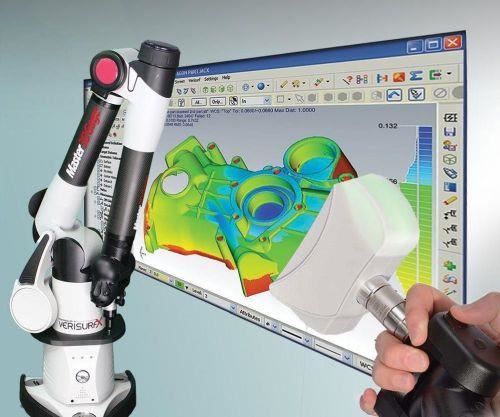

No matter what size moldmaking operation you may own or work at, you need inspection and measurement at critical stages of the process to drive efficiencies and profitability. So here are a few of the latest products we’ve heard about that you may also wish to see.

We all know that Moldmakers work with precision because customers expect their molded parts and products to work flawlessly in the way they intend them to. Moldmakers are still considered highly skilled craftsmen by many, but even they need to test and validate that molds and mold components are manufactured exactly right. Hence the use of many inspection and measurement devices, which is the focus of today’s Technology Showcase.

No matter what size moldmaking operation you may own or work at, you need inspection and measurement at critical stages of the process to drive efficiencies and profitability. So here are a few of the latest products we’ve heard about that you may also wish to see.

By the way, this topic is a good segue into MMT’s annual Leadtime Leader competition. If you haven’t already, please take a moment to click here and submit your application for 2017. We’ll announce the winners at Amerimold in Chicago. If you think your company is meeting and/or exceeding customers’ delivery demands, which inspection and measurement devices help you to do, then you are probably a good candidate for Leadtime Leader 2017! We hope to hear from you soon!

Related Content

-

Technology Roundup: New/Improved Technologies You Don't Want to Miss

With all the technology joining the market, moldmaking is a versatile, ever-evolving industry. As such, this technology roundup has no specific theme — it features a variety of products for applications and solutions across the industry.

-

CT Scanning Helps Micro Molder Reduce Cost of First Article Inspections

CT scanning services performed by 3D ProScan, a division of NyproMold Inc. provides MTD Micro Molding with accurate, high-resolution internal and external measurements performed about seven times faster and at significant cost savings.

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.