Setup Time Reduction Part IX-Determining the Cost and Benefit of Reducing Setup Time

The final part of this article series focuses on how an actual return on investment is the real measure of your efforts in reducing setup time.

Last month's article examined auditing the start-up after changeover and overcoming the resistance. This month's article, which is the last of the series, continues with how to determine the cost and benefit of reducing setup time - justification of expenditures, return on investment.

Determining Low Cost

It is recommended that the initial improvements to your setup time target those that are low in cost. This will allow you to reduce setup time, get an early payback and later on use the additional income to fund improvements that are more costly. A good definition of low cost is that it pays back in fewer than four months. It is important to the success of your setup time reduction program that you seek low-cost improvements first.

Calculating Return On Investment (ROI)

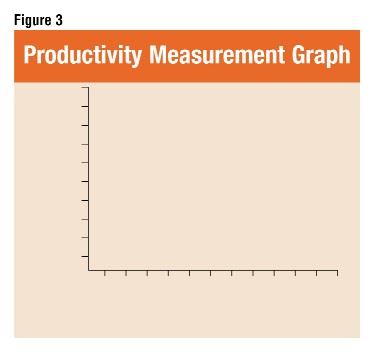

By providing an easy method to identify the Return On Investment (ROI), you will ensure that every recommendation for expenditure to reduce setup time provides an ROI calculation. If you have a formula in your organization to determine return on investment, that calculation should be provided and used by the improvement team. If one is not available in your organization, Figure 1 provides the formula to calculate ROI. By filling in each blank and doing the associated mathematical calculation, the items that return 30 percent or less are low cost, which means that they will payback in fewer than four months (30 percent of a year).

It is recommended that every purchase request be accompanied by this ROI calculation. Doing so will instill in your employees the need to find improvements that meet your payback requirements. This will keep you from having the automation first mistake. In most cases, low-cost improvements will result in as much as a 60 percent reduction in setup time and are easy to implement.

Key Drivers to Successful Setup Time Reduction

Time and money are key drivers in your continued improvement effort. If you begin working on setup time reduction and see very little improvement, effort will drop off. If you approach this initiative properly, you should expect to have 30 to 60 percent reductions in setup time implemented in fewer than two months. Doing so will demonstrate the importance to the organization. If you focused on low-cost improvements first, you will realize the financial return quickly and avoid the automation first mistake.

Automation First Is a Common Mistake

Many times, when employees understand that you need to reduce setup time, their first inclination is to develop and recommend automation solutions. Typically automation will provide a 15 percent payback. Relying on automation improvements is costly and when compared to the ROI calculation may take years to pay back. Usually in this environment, your setup time improvement fades away due to the cost. Many companies spend large sums of money to automate and still have the same inefficiencies of travel, transporting and tweaking during setup.

Getting the Return On Investment

It is especially important that management ensure that the payback is realized - because without it, this effort will die out. Payback is when you actually get the return on investment you predicted in the ROI calculation. It is recommended that you determine what would increase productivity for your shop and make sure those items are achieved as you reduce setup time. You can use the formula for productivity when determining if the efforts actually provide the payback.

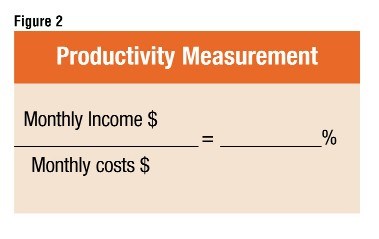

In most moldmaking shops, the return on investment for setup time reduction is generated from increased production time. By doing this you will receive faster invoice payment as a result of shorter leadtime. Increased sales should be generated due to less time spent setting up and more time producing salable product. This all results in higher income. Figure 2 provides the formula for determining the productivity measurement.

This calculation should be done monthly and reported as shown in the graph in Figure 3.

How to Determine If You Are Successful

If productivity is not improved, the effort has failed. There are cases where setup time is reduced, but productivity (output divided by input) remains the same. This cannot be accepted. Reduced setup time must be replaced with more output. Management must put special emphasis on the need to achieve the return on investment as a result of setup time reduction, and that return must be in the form of real income. This actual return on investment is the real measure of your efforts in reducing setup time.

Conclusion

Setup time reduction is an important improvement in our very competitive environment. We hope that this series of articles has provided enough information for your shop to implement setup time reduction. Getting focused, achieving results quickly and continuous improvement are the keys to success. You no longer have to accept setup time in your shop.

Related Content

MMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreRead Next

Aviation Component Supplier Cuts Setup Time With Productivity Partnership

This shop turned to a tool supplier to help cut milling time on one alloy steel hydraulic body by 63 percent. The success led to a broader Productivity Improvement Program that identified some $87,000 in potential annual savings, and ultimately to a $600,000 payoff by introducing a quick-change modular tooling system.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More