Roush Manufacturing: Fueling Growth

An in-depth look at the operations, core competencies, and business strategies of Roush Manufacturing.

Share

Moldmaker. Molder. Designer. Prototyper. Manufacturer. All of these words describe Livonia, MI-based Roush Enterprises—a multi-faceted organization that offers these services to the transportation, defense, aerospace, medical device, and consumer products markets. And they also race cars!

Roush Enterprises’ subsidiaries include Roush Industries, Roush Manufacturing, Roush Performance Products, Roush Life Sciences, and Roush Fenway Racing. While serving a multitude of markets, Roush Manufacturing’s specialty is designing and building tooling for automotive applications. “We generally build tooling that supports a given vehicle system such as an instrument panel, center console, or door system,” notes Mark Kunitz, Engineering Director. “To maximize value for our customers, we frequently bundle internally produced tools with tools produced by our Low Cost Country (LCC) supplier partners. We make the transaction completely transparent to the customer. In other words, we manage the risk and deliver to our customers, extremely cost effective tooling solutions.”

Operational Innovations and Strategies

Roush Manufacturing’s market offerings are complemented by the comprehensive development services offered by Roush Industries. “We are flexible and focused, and at our best when we’re challenged to think outside the box—critical traits when our success depends on how quickly we can take our customers’ visions from the sketchpad to the showroom floor,” states Business Development Director, Brian Weiler. “Our wide range of in-house capabilities and flexible processes allows us to develop solutions specifically tailored to each customer’s unique requirements. In addition to our extensive tooling, molding, and assembly services, we have seamless access to Roush’s team of design, styling, engineering and testing specialists.”

Roush Manufacturing Services/Tool Group

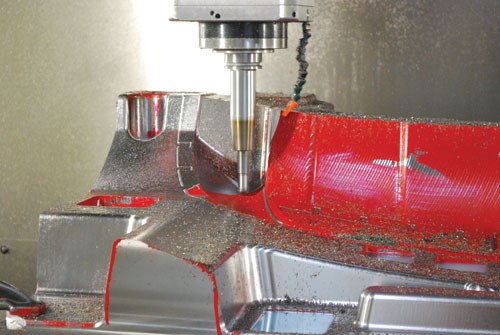

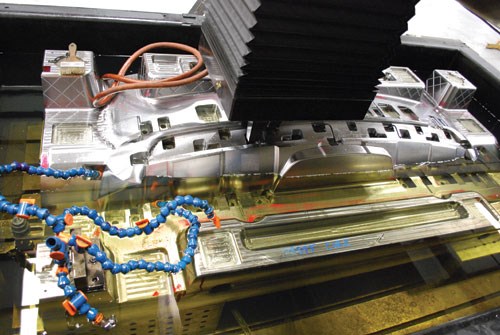

Roush Manufacturing is a two-plant operation, encompassing approximately 180,000 square feet of manufacturing space for mold tooling, contract machining services and rapid prototyping. The facilities contain more than 20 CAD/CAM workstations, 19 CNC machines, six sinker EDMs, a full service mold shop, six injection molding machines, on-site Mold Flow analysis and in-house CMM capabilities. Kunitz notes that Roush takes pride in its unique approach to the mold manufacturing process. “We utilize Advanced Product Quality Planning (APQP) tools to define each critical step of the entire value chain and bring all stakeholders together through this process to ensure our customers’ tooling is engineered, designed, manufactured and validated to their specific requirements.”

Roush also utilizes its robust engineering processes, design and machining expertise for delivering value in other areas. “In a nutshell, we leverage the manufacturing capabilities found in the moldmaking process into other products and services to lower our overall risk from the volatility associated with only one type of product,” Kunitz explains. “Accurately forecasting mold tooling sales is extremely difficult if not impossible, so we utilize a product and industry diversification strategy to lower demand uncertainty, but at the same time, are careful not to stray from our core competencies. For example, we contract milling and EDM services for niche products to the entertainment, oil & gas and aerospace industries. This strategy has put Roush Manufacturing on a steady growth trajectory as the company continues to expand its overall manufacturing capacity and capabilities.”

According to Kunitz, Roush Manufacturing is focusing on the emphasis of applying engineering principles into mold design and construction. “There is an increased focus on the application of FEA models for analyzing mechanical and thermal properties of the mold design, including structural and load analysis for tool size optimization.” Kunitz comments. “We want to move away from over building tools and instead, deliver well-engineered tooling that is optimized for the specific environment in which they will be used. Essentially, overbuilding a mold drives unnecessary costs without returning value for the customer.”

The company is also looking at the re-design of its downstream processes and continues to invest in new machining technology and strategies for organically growing a well-trained, high-tech labor force. Kunitz notes, “Merely acquiring high-speed machining technology is not in itself a competitive advantage; however, maximizing the capability of the technology is.”

As an example of how Roush is expanding its utilization of technologies, Kunitz explains one of many initiatives taking place that are delivering competitive advantage for the company, “We’re moving from a single programmer/set-up/operator job function in our finish milling area, to programming teams, set-up teams and mill operators,” he elaborates. “This approach improves programming consistency, creates competition, enhances individual career development and reduces overall direct labor costs.”

This type of re-design has helped Roush Manufacturing face industry challenges head-on. “The moldmaking industry faces some unique challenges,” Kunitz affirms. “The rapid introduction of new technology raises the barriers to entry due to the high investment costs, and although the technology can theoretically reduce overall manufacturing time/cost, realization relies on a well-trained and well-educated labor force. Additionally, globalization has resulted in tremendous downward pricing pressure on mold tooling—which amplifies the need for maximizing productivity and stripping non-value added content from tooling wherever practical is imperative. These challenges fundamentally change the approach to managing the business. We need to be process-driven, technology-focused, people-focused, and more vertically integrated to control more of the value chain.”

Roush Manufacturing also implements cutting-edge Rapid Prototyping (RP) technologies. “Rapid prototyping enables us to bring products to market quickly and efficiently by decreasing product development time while simultaneously providing manufacturing method and functional performance feedback,” states Weiler. “Our capabilities include Stereolithography (SLA), Selective Laser Sintering (SLS), Connex multi-material 3-D printing, silicone tooling/molding and rapid machining. With the many options available to our customers, we are able to match the correct method with the desired outcome for quality, functionality, timing and cost.”

Business Acumen

Roush Enterprises attributes its consistent growth to adherence to a carefully designed and executed strategy. Kunitz points out that the Roush Tool Group seeks to diversify its offerings of products, services, industries and customers through leveraging its core capabilities in program management, engineering, machining, fabrication and validation.

“Strategic realization is achieved by optimizing the entire value chain,” Kunitz elaborates. “The process begins with clear identification of customer value attributes. Identifying what is most important to our customers in each of our primary offerings allows us to focus on the critical areas to grow our infrastructure through capital investment, acquisitions, regional and global supplier development, and manufacturing diversification. Measuring and assessing underlying economic trends in each of the markets we serve has become critical in infrastructure development and overall risk management. Anticipating and responding to market trends and customer needs in advance of those needs is a competitive advantage and provides our customers with a high degree of value.”

Roush places constant emphasis on flawless execution of its APQP process by leveraging the synergies of cross-functional teams comprised of experts in finance, project planning, engineering and supply chain management to maximize value within each of its core product lines. “We have defined and optimized the value chain required to support each of the primary market offerings,” Kunitz says. “For example, we have streamlined the manufacturing of mid- to large-size automotive mold tooling in North America through improved design standardization, design/machine processing techniques, investment in new machinery and technologies, machine tooling and EDM for improved productivity, precision and accuracy.

Kunitz states that Roush Manufacturing’s biggest challenge is managing growth. “The financial barriers to expanding can be quite high, and the lead time required to establish the necessary infrastructure exceeds our ability to accurately forecast sales”, he states. “Because this results in higher investment risk, our investment decisions are driven by constant monitoring of economic conditions within the industry.”

“At the end of the day, our success remains deeply rooted in the core values that are unique to Roush: reliance upon the talent of the individual, a disciplined work ethic, scrupulous attention to detail, and an acutely intense desire to be the best,” Kunitz adds. “We continue to seek innovative methods of providing our customers with the highest quality products and services at globally competitive prices.”

For More Information:

Roush Enterprises / (734) 805-4415

Email: brian.weiler@roush.com / roush.com

Related Content

How to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreMMT Chats: 5 in 5 with Best Tool and Engineering

MoldMaking Technology Editorial Director Christina Fuges reveals 5 best practices for improving efficiencies within shops...in 5 minutes. Our guest is Joe Cherluck, President of Best Tool and Engineering in Clinton Township, Michigan.

Read MoreConfronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.

Read MoreRead Next

Niche Auto Molds Prove to Be a Profitable for Cavalier Tool

Capitalizing on its specialty of molds for fans and shrouds in the automotive industry—on their own terms with no PPAP—drives this moldmaker’s success.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More