October held some tricks but mostly treats for MoldMaking Technology’s audience. We covered various topics including—but not limited to—R&D credits for mold builders, the benefits of aluminum tooling, marbles (yes, marbles!) and much more! Take a look at what you might have missed from our top ten most popular articles in October.

10. VIDEO: What You Need to Know about the R&D Tax Credit Today

A team member from Strike Tax Advisory reviews the tax changes that are impacting the R&D credits for mold builders.

9. Five Benefits of Aluminum Tooling

Aluminum molds are worth a second look as a viable means to swiftly and cost-effectively get products to market.

8. MMT Chats: How Moldmakers Impact New Product Development

Dynamic Tool Corp. discusses the mold builder’s role in defining injection molds to support new product development with MMT Editorial Director Christina Fuges. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

7. MMT Chats: Molding, Mold Design, Project Management and Marbles, Part 2

MMT Editorial Director Christina Fuges continues her conversation with MMT EAB Member Mike Close of SMC Ltd. We chat about master molders, project management/mold design, and yes, marbles! This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

6. VIDEO: Why Is Sustainability Important to Mold Builders

Marta Orozco with DME shares ways mold builders can be a part of building a more sustainable future.

5. Laser Welding Repairs Micro-Threaded Inserts Fast

Moldmaker/molder Medbio LLC sent unscrewing cores with damaged micro-threads out for repair via laser welding and polishing, slashing nine weeks off lead time to produce new inserts.

Photo Credit: Medbio LLC

4. The Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D-printed parts.

3. What Is the 2023 “Customs & Practices of the Moldmaking Industry Guide”?

Are you aware of the updated “Customs & Practices of the Moldmaking Industry Guide”?

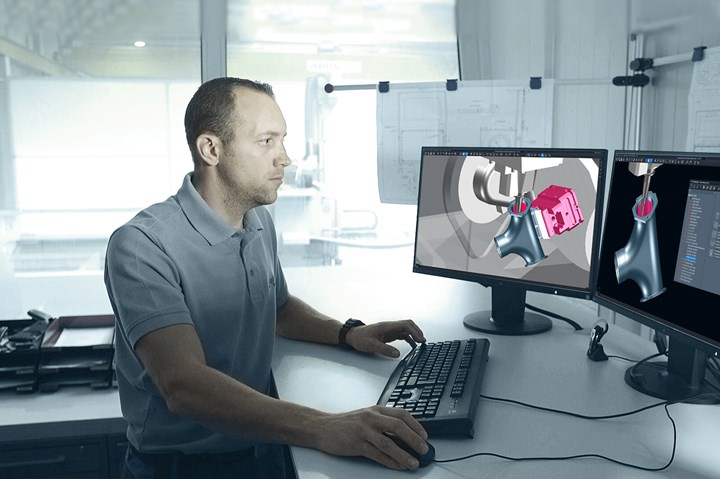

2. How to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

Photo Credit: Tebis

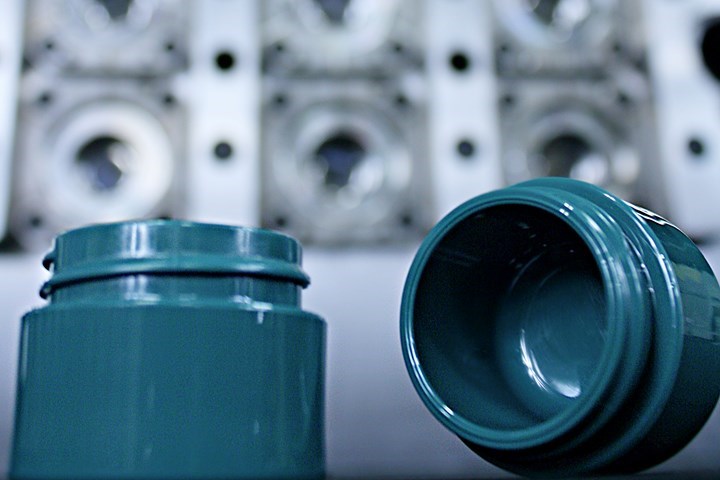

1. Take Time to Save Time: 6 Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these six steps in the design phase can save three weeks or more in an overall tool build.

Related Content

-

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.