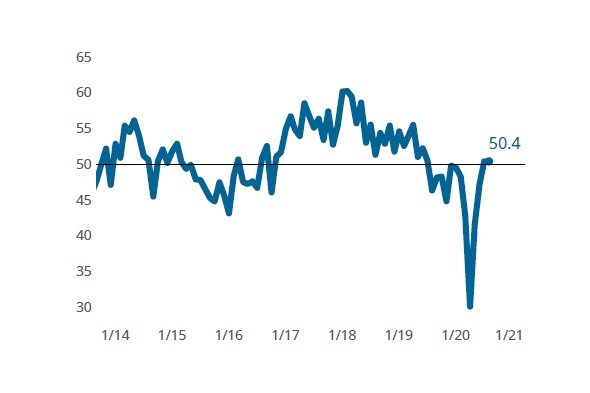

Moldmaking Index Registers Second Straight Month of Modest Expansion

Strong expansion in production and quickening supplier deliveries hint at a rebound.

Moldmaking Business Index: The Moldmaking Index expanded for a second consecutive month in August. The expansion was chiefly supported by a near 7-point increase in production activity along with smaller advances by most other Index components.

The Gardner Business Index (GBI): Moldmaking registered a second consecutive month of expanding activity in August, repeating its July 50.4 reading. An examination of the individual components saw new orders expand for a third straight month while production and employment activity both expanded for the first time since before the pandemic crisis. Export and backlog activity both extended their contractionary readings for another month, suppressing further gains. Moreover, supplier deliveries readings fell more than 9 points in August to a reading slightly above 50, marking the most significant one-month change in supplier delivery activity in recorded history.

Sharp Drop in Supplier Delivery Reading May Signal Improving Upstream Conditions: The COVID-19 pandemic’s disruption to business operations has resulted in elevated supplier delivery readings since February. August’s 9-point decline is the largest one-month decline in recorded history and may signal that upstream product flows are improving.

Unlike the textbook example of a recession, the COVID-19 pandemic’s economic impact on manufacturing has been unique because of its shock to both demand and supply. In a classic recession there is a reduction in the demand for goods which lowers sales; differently, the pandemic has further reduced sales because even with a willing demand for a product, there may not be a product to sell due to disruption in the supply chain. Whether lost sales are caused by a shift in demand or a lack of available supply, the impact to the economy is the same. As supplier delivery readings continue to normalize and new orders readings continue to move higher, it appears that the industry is taking the right and necessary steps for a successful recovery.

Related Content

-

Moldmaking Industry GBI Contracts for Four Months Straight

The GBI Moldmaking ended the month at 45.8, down one point from June, with components contracting or nearing contraction activity.

-

Contraction is the Consistent Trend for Moldmaking

The August Gardner Business Index (GBI): Moldmaking saw more of the same contraction activity that has been reported the last four months.

-

Moldmaking Activity Contraction Slows in August

Future business expectations still improving, but more slowly.

.jpg;width=70;height=70;mode=crop)