MMT Chats: New Quick Response Shield Design Was a Labor of Purpose for This Wisconsin Mold Builder

Stellar Mold teamed up with another local Wisconsin company (Spartek Inc.) to be a part of the fight against COVID-19 and both worked to design and manufacture a new quick response face shield.

Stellar Mold & Tool

Daniel Vest is in charge of business development at Stellar Mold & Tool in Galesville, Wisconsin, and despite being busy spent 30 minutes with me to talk about the Stellar team and the development of a new face shield design—quick response shield (QRS).

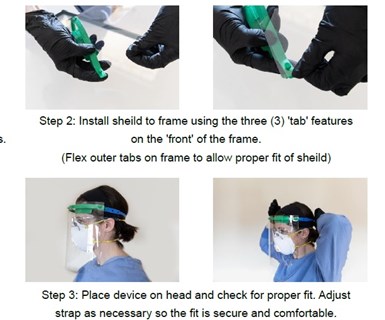

Each Quick Response Shield (QRS) kit contains a frame, adjustment strap, and 13" x 9" clear PET face shield.

Product Highlights:

- The QRS offers full facial protection from spray/splatter as a semi-disposable PPE solution with the ability to quickly change shields as needed.

- Provides adequate clearance for most eye protection and respirators/masks to be worn beneath the face shield.

- Adjustable strap (TPE) and frame (PP) are molded commonly used materials and maybe easily disinfected for reuse.

Stellar Mold has been in business for over 40 years and has built molds for the automotive, consumer/industrial electronics and the medical industry, to name a few. Just recently they have built several complex unscrewing molds for medical customers and are looking to further expand their share of that market.

The 411 on QRS

Stellar’s focus is on parts with difficult-to-mold features, but the QRS project was designed specifically to be very simple and straightforward.

“This project started when one of our long-standing customers, Spartek Inc. Sparta, Wisconsin, approached us after watching the news one night and saw the stories about people using 3D printers to make face shields. But as anyone in the mold and plastics industry knows, to scale 3D printing to fit the level of production required during this crisis would be near impossible,” Vest says.

So President Jeff Stegemeyer looked at the common poly die-cut shields (with a piece of foam and a rubber band) that were on the market, and decided to design and manufacture a frame that is exponentially better and re-usable.

By using common injection molding materials, the Stellar Team designed a reusable frame to be used with an injection-molded strap and existing replaceable die-cut face shield. Stellar foresees these types of products being easily and inexpensively stockpiled and re-used as opposed to some of the more permanent and more expensive solutions on the market.

To fully design and produce an acceptable part in a CAD system and the mold itself took fewer than four days, even with an existing backlog at the time. The actual mold construction took about three days after Stellar received the necessary materials from its vendors, such as Progressive Components, PCS, and DME.

“Our suppliers really stepped up to the plate to turn this stuff around for us,” Vest says. “We would be nowhere without our suppliers.”

Stellar turned the entire process around, from concept design and initial phone calls, to a finished and sampled, production quality mold in under 10 days.

Lessons Learned

Stellar has always worked with our customers upfront to review and ask as many questions as possible so that we can offer the customer the best product to fit their specific needs. However, this project was special. By controlling the entire process, Stellar was able to sidestep many of the roadblocks that can present themselves in a more traditional project.

Being completed entirely ‘in-house’ the team at Stellar was able to utilize their extensive experience to design a product that was not only fully functional but also easily moldable and with minimal constraints of some more traditional projects.

A key component of this project was the absence of any roadblocks, according to Vest. Stellar controlled the part design. “Most of the time, it's just a matter of posing the right questions to the customer about key design aspects. If we can convey this information to a customer early on, it can change the entire delivery of a tool,” Vest says. This can go a long way to make sure that Stellar is always delivering a mold that the customer wants.

What Stellar reinforced and relied upon during this crisis is the importance of getting all necessary individuals involved in the entire process. That way, the people who will be doing the machining or electrode work, know exactly what is expected upfront. A good example can be a simple change to a radius in the final part design can mean a substantial shift from EDM to regular CNC machining.

It’s all about communication according to Vest, and communication methods are changing. This crisis has made the team look at, not only how they communicate within the shop, but also how they communicate with customers and how things flow and move through the shop.

For example, Vest explains that they recently had a customer who was coming up on a PM and did not want to ship out the entire mold due to the various moving parts and overall complexity, (the mold has unscrewing mechanisms on both the “A” & “B” sides). “The customer was worried about the A side unscrewing mechanism and some gassing issues. Due to the pandemic, Stellar did not want to send a toolmaker out for a site visit, so, we walked them through the virtual design and disassembly process using WebEx and CAD software,” Vest says.

He believes this may become the norm moving forward—instead of a site visit, instead of sending a toolmaker out to a shop to troubleshoot, it may just be a step-by-step virtual service call.

In the end, Stellar Mold & Tool and Spartek Inc. have donated approximately 20,000 shields to local entities. The team’s goal was to fill the critical PPE gap in its local community, now they are looking to continue to fill this gap and recoup some of the costs associated by continuing to produce and sell the QRS device.

“We're very lucky here with our leadership. They keep us involved and engaged. Everybody is a part of the process. The biggest thing is to not let people get complacent. Make sure that they know that they're valued and then everybody wins,” Vest says.

Related Content

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

MMT Chats: COVID-19 Highlights Value of Diversification

I sat down with a trio from Decatur Mold Tool & Engineering in North Vernon, Indiana, for a quick chat about their recent COVID-related project and a couple of lessons the team learned.

Read MoreMMT Chats: Remoting, Reaching Out and Ramping Up Recyclable PPE

Two members of the Axiom, Intex Tooling and Smart Attend team chat about COVID-19's impact on the business, employee morale across the business units, and the switch to producing and selling recyclable face shields.

Read MoreMMT Chats: Fighting COVID-19 with Collaboration

Next Chapter Manufacturing, Muskegon Community College, PCS Company and Concept Molds chat about a coalition they formed to produce face shields to help fight COVID-19.

Read More