Maintenance Supervisors: What You Should Know, Part 2

Mold scheduling and status.

When a mold maintenance supervisor walks through the door of his plant, chances are he will be greeted by someone in obvious stress, noted by the bulging veins and eyeballs. Typically this stress will concern a mold that is supposed to be running but for some reason—usually unknown—it is not. When this happens, the urgency of the breakdown will be conveyed during an animated walk to unlock his office. From there a trip to the toolroom or molding floor will ensue to look at the problem firsthand to try and figure out how the mold can be patched up and returned to the front line until it breaks again.

So the supervisor takes corrective measures to put the fire out, or at least make a plan. And as one fire fades, another one smolders. It is what it is. It’s the nature of the job. It comes with the territory, whatever. But once the fire is out, then what?

Even though the firefighter hat is worn during many hours of a supervisor’s day, there will still be time to be proactive in this job. So as crazy as it might sound, let’s look at what we are doing in between fires.

Scheduling Work

The next dilemma usually involves whether or not a mold that is scheduled to run is Blue-Tagged (production ready) when the setups head to the rack to retrieve it. The obvious idea being: there is no idle time for the press while process waits on the toolroom to get a mold ready. Scheduling mold PMs or C/Rs (clean and repair) accurately depends upon a few critical factors:

The ability of the company to forecast sales so the toolroom supervisor will know what molds or products will be needed in the next week, or better yet, the next month.

This might be impossible or a difficult challenge in some custom molding plants, but many captive molders that could work up a list of molds or products that are warming up still don’t do so. It is a huge advantage for a supervisor to at least have an idea of future production. Obviously it becomes apparent in some cases, over time, which molds need to always be ready, and having them ready is just standard operating procedure. Other products or molds can sneak up on you at the wrong time and completely disrupt a repair—or worse—a production schedule. Now molds don’t get fixed—they get patched—because there is no time for the appropriate repairs.

Adequate headcount in the shop to get the job done.

• American companies continue to go lean to the bone especially in maintenance, by not replacing those lost through layoffs or retirement, or not hiring additional help when more molds are acquired. If headcount is minimal, the only work that gets focused on involves breakdowns.

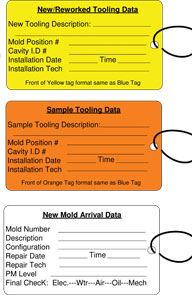

Tag examples. Images courtesy of MoldTrax.

Necessary tooling available to make repairs or change-overs.

• Too many times, molds get pulled for maintenance when no tooling exists in-house to make the repairs. More wasted time. To minimize this, maintain an accurate inventory count based on historical issues of past defects—if keeping 25 percent of mold tooling inventory on hand is not practiced or possible.

No new problems or surprises encountered during certain stages of repair (disassembly, corrective action, cleaning, assembly and final check).

• Once more, if mold condition and past defects are not diligently tracked, it will result in extended downtime while we wait for the right tooling, person or the time to make necessary repairs. Then production has to scramble—and change their schedules—to better utilize a down press.

Supervisors working for companies that engage in the short-run (JIT) philosophy (two to four hours then pull or changeover) have a much tougher challenge than those that have predominantly long runs and the option to pull molds based upon cycle times or production hours. With short runs, it is common practice to run and pull a mold without the toolroom ever knowing it happened. Then one day, the mold will develop a problem and the supervisor or repair tech will scramble to discover the sequence of events since it was last in the shop. This must be done in order to troubleshoot effectively and ascertain the root cause.

Some companies perform as many as 20 changeovers per shift—which left undocumented—can monopolize shop hours and does not promote proactive maintenance. But there are steps we can implement to keep up with any MPP (mold pull pace).

An Old Idea

A critical part of efficiently scheduling work through the toolroom lies in our ability to quickly and accurately understand a mold’s current production condition.

An old industry (but still best practice) method of using color coded tags on molds was popular for awhile, and then faded with advent of inventory control modules in ERP and CMMS systems. Physically tagging and entering mold locations and status seemed redundant, so tagging went away. This works only marginally. Although more people had access to mold status, if someone forgot to electronically update the information, molds get set that still need to be cleaned, repaired or changed over. So the mold is pulled again. One mistake like this can waste more time through investigation than would be spent physically applying tags to many molds throughout a year, so the practice of tagging is not without merit, if a few steps are taken to streamline the process.

Systems that Work Are Convenient

To make this system easier, tags of the appropriate color should be placed within close proximity to where they are used (i.e. red, green for the process floor and everything else in the toolroom). There are several methods to affix tags to the mold, with the most popular being wire or nylon ties. Tags can be made in many shapes and sizes of plastic or paper. A mold’s working environment dictates tag material.

The format of the tags should ask for specific information versus simply giving space for a freehanded journal entry of normally incomplete or illegible data (see tag drawings). How much data required on the tags will be based upon how much data is available in the electronic system versus how much redundancy one is willing to accept filling out a tag. Conversely, some companies do not write any data at all onto the tags, serving only as a visual alert to investigate the database for current issues. Better than nothing, but still forces you to go to a PC.

Storage Alert

If molds are stored in typical racks or on pallets on the floor, it is handy to be able to walk up to one and read the data on the tag versus logging into a computer to see why it is anything but blue. A typical rack normally does not have molds positioned by color, so it is handy for the tags to be accessible from the exposed side of the mold for a ready reference.

Tag Accuracy

Tag data tends to be accurate in most cases because of the visual reminder to change the color of the tag during different production or repair stages. It would be unusual for a tool repair tech to blue-tag a mold when a bright red one still hangs from it. And if a mold setter sees a red tag hanging from a mold that is stored 15 feet in the air, they will electronically check things out before even removing the mold from the rack, let alone setting it.

And for those short orders, a mold that is run, pulled and put back on the rack, without going through the toolroom will either have several green tags hanging from it, or one updated tag that documents all the runs.

Mold Status Colors Industry standard colors and definition for tagging are usually like this (see drawings above for tag verbiage):

- Red: Mold has issues and should be repaired before next production run.

- Green: Mold has run, but has no issues and is still cycle safe or under run hours and is production ready.

- Blue: Mold has been cleaned and repaired (or PM’d) and is deemed production ready by the toolroom.

- Yellow: Mold ready to run, but has new tooling installed that requires a part re-qualification by Q/A (medical companies).

- Orange: Mold ready to run, but has sample tooling installed that must be removed or blocked off before running standard production.

- White: New mold arrival (either a new mold or one transferred from another facility) requiring inspection or the application of specific Final Check procedures.

While the majority of plants use red, green and yellow tags to denote mold status, the color used for each status is not as important as the idea of standardizing mold status within a company and being able to physically see the current status of every mold in your fleet—as it moves about the plant—so that mistakes are not made.

A useful practice when set up correctly, don’t go overboard with tagging and try to make it what it will never be: an accurate documentation system. Some use the tagging system exclusively to not only denote mold status, but to manually document run and repair problems and corrective actions. This is not an efficient method because too much tag data inherits the same problems as any manual entry system. Ambiguous, unformatted, illegible, incomplete and inaccurate are descriptions that come to mind.

Summary

Electronic tracking will never lose its flavor because current mold status will always be important data to many individuals/departments that need this information to do their jobs. For the toolroom supervisor, it also is helpful to be able to electronically create a report that displays the status of all molds in your fleet for scheduling purposes and to keep track of your backlog of work.

There is much more to running an efficient repair shop that putting out fires. Having molds ready to run when needed requires departmental coordination through team effort and a commitment to standardizing practices. Those that have established methods and the discipline to document will reap the benefits of reducing costly mistakes while optimizing labor hours during the mold run/repair stages.

Related Content

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreMMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreDynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreRead Next

Maintenance Data for Processing Technicians

Data that processors need and what they should collect.

Read MoreThe Final Check

A simple mistake can be catastrophic for both sales and the mold, making a final checklist a must.

Read More