Linked In

With mold manufacturers looking to maximize machine productivity and many implementing some type of machine tool monitoring, I thought it was time to share with you a solution that MMT"s sister publication Modern Machine Shop has shed some light on: MTConnect--manufacturing data anywhere, at anytime, from any device to any software application.

With mold manufacturers looking to maximize machine productivity and many implementing some type of machine tool monitoring, I thought it was time to share with you a solution that MMT"s sister publication Modern Machine Shop has shed some light on: MTConnect--manufacturing data anywhere, at anytime, from any device to any software application.

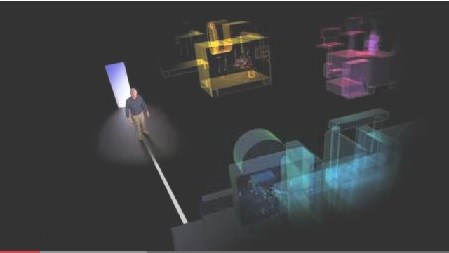

So what is MTConnect®? Well according ot the MTConnect Institute, it is "an open, royalty-free standard that is intended to foster greater interoperability between devices and software applications. By establishing an open and extensible channel of communication for plug-and-play interconnectivity between devices, equipment and systems, MTConnect allows sources to exchange and understand each other's data. That common communication is facilitated by XML and Internet Protocol technology to provide managers with near real-time data from throughout a factory. This thus empowers them to develop applications aimed at providing more efficient operations, improved production optimization and increased productivity."

And what makes MTConnect unique is that it is not a "proprietary hardware or special-purpose software. Rather, it is an open, royalty-free communication standard that utilizes Internet communications technology to link machines and systems together. Think of it as a dictionary to enable devices to speak in the same language. To help in this effort, example software has been developed to test the standard's soundness. That software can be downloaded from the MTConnect website and used as a template to create one's own software interface that meets the requirements of the standard."

To learn more click here.