Linear Motor Technology for CNC Die Sinker EDMs - From the Operator's Perspective

Linear motor EDM technology provides great advantages for today's EDM operators. It not only makes the lives of EDM operators productive and efficient, it also opens up new worlds of possibility for product planning.

Linear motor-driven EDM die sinker machines offer both increased cutting speeds and improved machining accuracy without flushing. Since the machine was introduced in 1999, users are continually finding new advantages to this technology. The EDM machine's servo systems use linear motors instead of traditional ballscrews. Linear motor technology also has been used in other machine tools such as machining centers as well as magnet-propelled trains. Since linear motors have no ballscrews or couplings, there is no metal-to-metal contact or backlash - thus providing smooth and accurate movement at high-axis speeds.

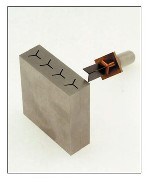

The construction of a linear motor is shown in Figure 1. A series of magnetic plates are mounted to opposite sides of the axis quill. Fixed magnetic coils are also mounted to each side of the axis. A linear scale with four millionths resolution is then mounted to the axis quill in order to detect the axis movement and location. As the control tells the axis the destination, the magnetic plates change polarity - thus moving the axis quill. The Z axis can travel up to 36 m/min. and the X and Y up to 10 m/min. as compared to non-linear EDM speeds around 1.3 m/min. By creating this high-speed jump, it can displace particles located in the spark gap - creating natural flushing and providing a uniform and minimum spark gap.

This no-flush technology is especially helpful to both inexperienced and experienced operators. An operator no longer has to guess the best place or size for flushing holes or guess at the flushing pressure. Eliminating flush holes is a big advantage with multiple electrodes and multiple cavities. An operator no longer has to worry about staggering flush holes in electrodes or about flush lines getting in the way of tool changers.

Since linear motors generate a lot of heat, coolant pipes were added throughout the magnetic coils to keep them at a constant temperature as seen in Figure 2. The linear motors have high axis acceleration speeds that would create problems with the original counter-balanced head. To overcome this, an air cylinder is used to bring the lightweight ceramic Z-axis to sudden stops. This design also prevents the Z-axis from dropping down after power is shut-off to the machine.

From an operator standpoint, linear motor technology allows users to EDM samples that were once thought of as impossible or impractical to do on a non-linear EDM. Following are some tested samples that best show the capabilities of linear motor EDMs.

| Going deep Material: Gr-D2 Electrode size: .04" x 1.1" Depth: 4.0" Surface finish: 43 RMS No flushing A 4" depth with no flush can open a new world of EDM possibilities. |

|

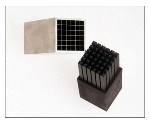

| Honeycomb shape Material: Gr-D2 Electrode size: web .006" Depth: 1.0" Surface finish: 43 RMS No flushing This sample would be impossible to burn on a non-linear EDM. The parts can be individually wire cut and assembled, but this would drastically increase the total machining time. |

|

| Y shape Material: Cu-D2 Electrode size: .02" x .196" Depth: 1.0" Surface finish: 50 RMS No flushing Because of the electrode's size and shape, flushing would be very difficult. |

|

| Thin walls Material: Gr-D2 Electrode size: .120" x .120" with .03" web spacing Depth: 1.0" Surface finish: 43 RMS Wall thickness: .005" No flushing This electrode is burning 36 cavities at the same time. It may be possible to burn this on a non-linear EDM with flush holes through the electrode, but it will then be difficult to extract the flush hole tips from the cavity. |

|

| Multi rib burn Material: Gr-D2 Electrode size: .04" x 1.02" Depth: 2.75" Surface finish: 32 RMS No flushing With 16 ribs on one elecrode, this burn would be impossible on a non-linear EDM without flushing. |

|

| V rib Material: Gr-D2 Electrode size: .012" x .196" x 1x Depth: 1.57" Surface finish: 50 RMS No flushing The depth and shape of this cut makes it very difficult to remove the chips. This thin, fragile-shaped electrode can vibrate if too much flushing was added to the burn. |

|

| Sphere Material: Gr-D2 Electrode size: .750" O.D. Depth: .650" Surface finish: 64 RMS No flushing This sample would take twice as long to burn on a non-linear EDM. |

|

| Subgate Material: Gr-D2 Electrode size: .040" O.D. Depth: .250" Surface finish: 64 RMS No flushing For this short depth cut it would take the same time as non-linear EDM, but it does not require flushing. This is helpful in multiple or unattended operations since flushing for each setup is not required. |

Application Story

Clarich Mold (Westchester, IL) was one of the first U.S. companies to purchase a linear motor sinker EDM. Clarich Mold is a mold builder and a member of the American Mold Builders Association (AMBA) that specializes in difficult to build injection molds and diecast dies. It purchased the machine after witnessing a deep rib burn with no flush. Bernie Terpening - EDM operator for Clarich - has been running EDMs since 1973. After using the linear motor sinker EDM, he thought that the linear motor EDM is very accurate and easy to get up and going because you do not have to consider flushing. Terpening states, "It is a worry-free machine requiring very little setup time that makes us more productive and gives us time to do other things."

| Clarich Mold |

| Type of shop: Mold builder Size of shop: 20 employees Years in business: 30 years Purchase justification: Latest technology, no flushing results in less setup time. Flushing preparation can be very time consuming. Less maintenance to learn and worry about since there are no ballscrews. You don't have to worry about ever replacing ballscrews and the expense of their replacement. Learning curve: It was not any more difficult to learn than any other EDM technology. |

Linear motor EDM technology provides great advantages for today's EDM operators. It not only makes the lives of EDM operators productive and efficient, it also opens up new worlds of possibility for product planning in addition to opening up the door to EDM'ing that was thought as impractical or even impossible. In order to stay ahead of the competition, today's mold builders have to keep a keen eye on what new technology the industry has to offer.

Related Content

Integrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreMold Builder Meets Increased Domestic Demand With Automated Cells

Burteck LLC experienced significant demand increases due to reshoring and invested in automated machining cells to step up its production output quickly and avoid losing business.

Read MoreRead Next

How to Increase the Process Speed of Die Sinking EDM

An increase in productivity of approximately 30 percent, and up to 100 percent with pre-milled molds, is possible with new EDM technology.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More