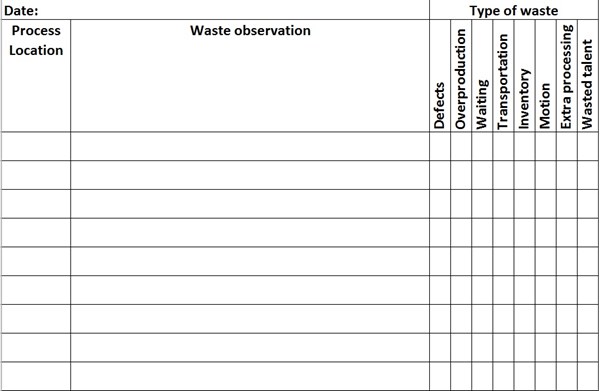

Lean Waste Walk Form

Spreadsheets are a common tool in mold shops and we've touched upon their various uses in MMT. Here is another example of using spreadsheets to help create an organized way of viewing and tracking info. This time it has to do with waste.

Steve Brammer has worked for a variety of custom and captive molding operations in manufacturing and process engineering roles ranging from engineer to engineering manager. He also serves as an adjunct instructor for Grand Rapids Community College teaching plastics and manufacturing classes. He shares industry insight regularly via his LinkedIn page and this post caught my attention, so I wanted to share it.

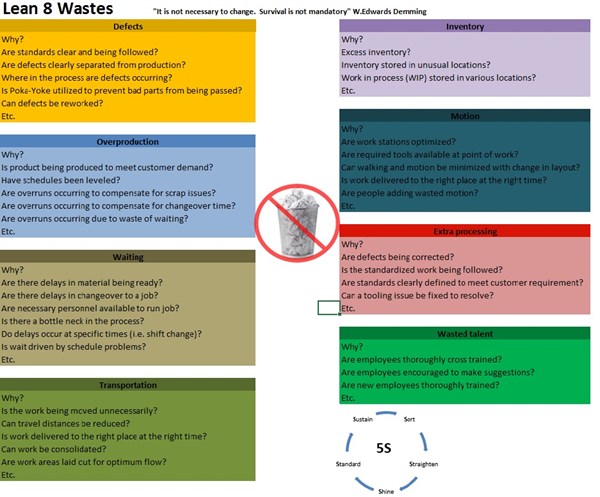

Here is a form Steve developed to use when conducting lean waste walks. The purpose is to serve as a reminder of the different forms of waste and make it easy to note observations. Of course the form itself is also waste, but it serves the purpose it was intended for, when people become skilled at waste observation the form can be eliminated. Just another example of utilizing spreadsheets to help create organized ways of viewing and tracking info.

Related Content

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.