Laser Engraving Boosts Welder’s Capabilities

The addition of laser engraving services has boosted this Ohio welding company’s business by about 10 percent.

For 14 years, Wicked Welding in Dayton, Ohio, has provided welding services to the mold, tool and die manufacturing industries. It also offers carbon dioxide-type laser marking services to apply codes, part and revision numbers onto mostly anodized aluminum parts and other non-ferrous materials such as wood or glass. However, according to owner Peter Mourouzis, laser marking wasn’t quite cutting it for some customers.

“We were getting by with laser marking, and we do a lot of it on parts for aviation and medical industry customers, but it wasn’t enough. Our mold and die customers wanted engraving,” he says. They would bring items to us for welding, and then send the jobs elsewhere for the engraving. We could have provided the surface-finish work of machining and polishing, but because engraving is done before those finishing steps, we were losing two of the three jobs plus potential work as well.”

In order to bridge that gap, last December the company purchased a FiberStar open workspace laser marking system from LaserStar Technologies. Although Wicked Welding already had been using a Worldwide Laser 50-watt marking machine for its laser-marking jobs, this system is a multi-tasker, able to mark, engrave and cut using a pulsed-fiber laser. The addition of laser engraving services has boosted the company’s business by about 10 percent, Mourouzis says.

Marking vs. Engraving

There are critical differences between laser marking and laser engraving, Mourouzis explains. Marking entails either placing a surface mark onto a workpiece that does not have a surface coating using an annealing process or, if the piece is coated, laser marking removes part of the surface coating and leaves a mark that can be easily seen, similar to a tattoo. It feels smooth to the touch. This is ideal for cleanroom applications, particularly medical applications, in which items like surgical instruments need identification marks but cannot be contaminated with germs or other impurities.

One of the problems with laser marking on molds and dies, however, is that the markings can wear off if the workpiece is abrasively blasted or during cleaning with caustic cleaners such as sodium hydroxide or sulfuric acid, which is common in mold repair. In addition, markings can gradually disappear simply due to normal surface wear during production.

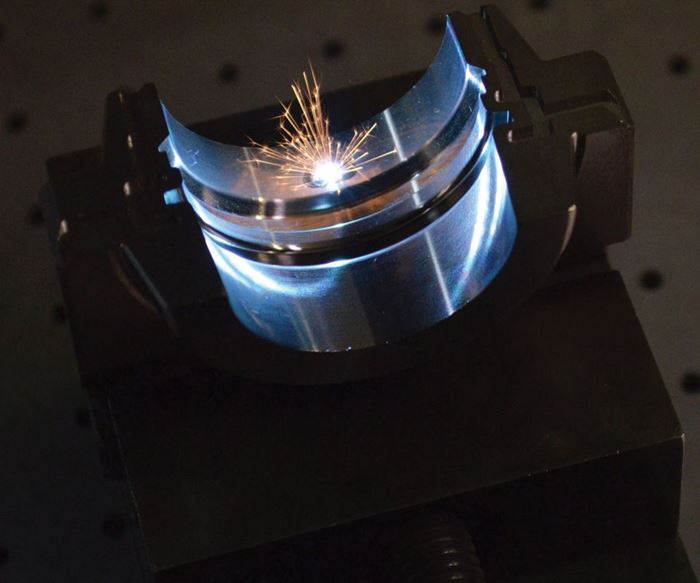

Etching, on the other hand, actually removes some of the base material so that the desired impression is engrained, either finely or deeply, into the surface of the mold, Mourouzis explains. That impression could include part numbers, revision numbers, bar codes or logos. Wicked Welding is often directed to laser-engrave codes or dates onto mold cavities in reverse so that those codes or dates will appear raised on the surface of the actual molded parts.

Almost any metal material can be laser-engraved, including brass, stainless steel, carbide, copper, titanium and aluminum. Laser marking is much faster than laser engraving, however, requiring only five or six passes with a laser rather than hundreds of passes to produce the same graphic.

Laser Engraving vs. Machining

Nick Garman, Wicked Welding’s shop foreman, heads up the company’s laser engraving department. As someone with a moldmaking background, Garman says he knows it’s not uncommon for moldmakers to machine engravings in house, especially if it’s just on flat surfaces, but this can be costly in both money and time if the part has some curvature to it.

“It’s faster and much less complicated to laser-engrave versus engraving a workpiece using a traditional end mill because more programming is involved,” he says. “A CNC doesn’t know what the letter ‘A’ is, for instance. To mill each of the numbers and letters you have to tell the CNC to go from ‘arc’ to ‘straight’, and vice versa, to form each item.” Setting up the machine also adds time and costs to the job. “With laser engraving, we simply type in the text and the laser engraver knows where to go.”

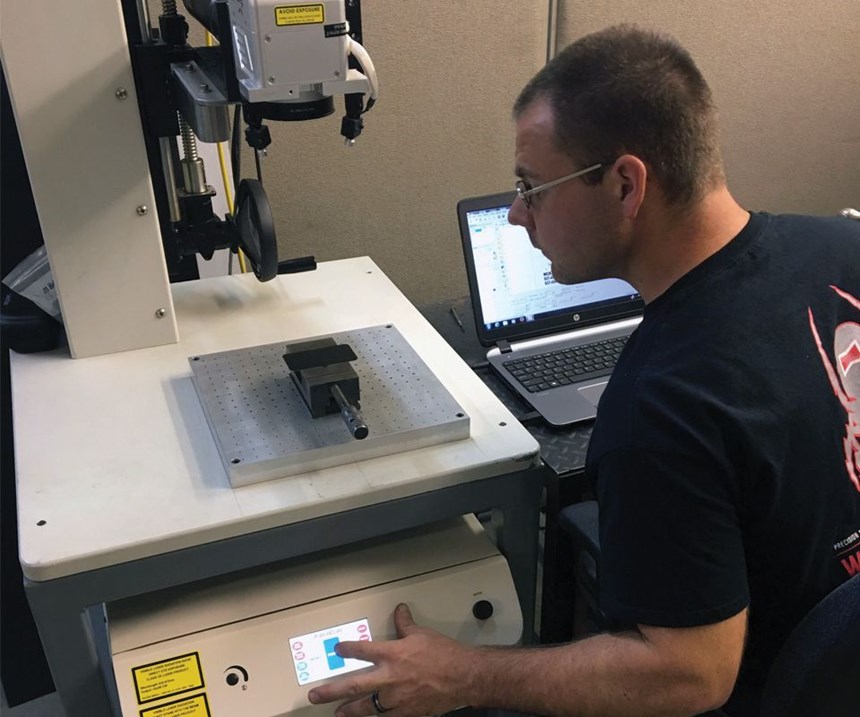

One recent job involved engraving three numbers to a depth of about 0.012 to 0.015 inch on a mold for the bottom of a 5-gallon bucket. It took Garman about three minutes to orient the workpiece, which did not need to be clamped down, and 15 minutes to program the FiberStar machine. Actual burn time was only about six minutes. If the numbers had been milled using CNC, the setup and runtime would have taken three to four times longer, he says.

The size and wattage of the laser engraving system contributes to difference in speed between machining and engraving. “If you want to go deep, go fast and save time, you have to buy more laser capacity in terms of power. Wattage equals speed,” Mourouzis says. Wicked Welding’s FiberStar system operates with 30 watts of power and accommodates workpieces that are very small to as large as a bread box. It is an open system, meaning there is no enclosure, and the laser is mounted on a moveable head, so it’s just as easy to work on a part that is 16 inches long as it is to work on one that is 6 inches long, but the operator is still constrained by the system’s operating area, which is determined by the size of the lens. The lens on the model that Wicked Welding purchased can engrave a surface area as large as 7 inches by 7 inches, but the company already is discussing how it can expand this size limit and plans to purchase a rotational fixture to help with laser engraving of round parts.

Because the engravings for molds and dies that Wicked Welding performs are very small (typically 0.015 to 0.020 inch), machining them would increase the risk of breaking end mills, especially if the machining programs are run too fast, and this can be very expensive. One customer had been machine-engraving onto a part made of brass, which, although a soft material that some might expect would be easy to machine, tends to get “kind of gummy” from cutter friction and builds up on the cutter. The customer told Garman it was going through $150 worth of cutters for each part it machine-engraved. “By laser engraving the workpieces for them, we save them hundreds of dollars in cutters every time that job is run,” he says.

Short Learning Curve

Wicked Welding currently owns two LaserStar laser welders, a 7000 Series 80-watt workstation and a 7700 Series 200-watt universal jig workstation, so the team possessed a basic understanding of how laser engraving works when the company took delivery of the FiberStar system. Mourouzis says the machine was up and running in a day or two, and Garman was quickly running simpler jobs. Most of the learning curve came with manipulating more complex graphics using the laser engraving software provided by LaserStar.

It’s not uncommon for a job to consist of only one part to be engraved, giving Garman one shot at getting it right. To ensure success, even on a job with multiple pieces, Wicked Welding stocks up on scrap aluminum, steel, brass and other materials so Garman can engrave a test piece for each job first.

The fact that the Wicked Welding team has moldmaking at its roots also helps the shop ensure that its work meets the customer’s requirements. Mourouzis himself has eight years of experience as a moldmaker, which led him into the welding business. “We know what mold components are, how molds are built and when something doesn’t look right. It’s an advantage that helps us avoid communication errors with our customers,” he says. “We want to fix the problem, not add to it.”

Adding the FiberStar system to its repertoire of capabilities has helped Wicked Welding better serve its customers. “This machine has signified a breakout opportunity. It gave us a completely new capability,” Mourouzis says. “Now we provide customers with a comprehensive array of service options under one roof, saving them time and reducing costs.”

Related Content

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreWhat You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreRead Next

The Right Welder for the Job

For this shop, determining which welder is best for any given job goes beyond choosing between laser and micro-TIG. The configuration of the machine matters, too.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More