Hot Runner Data Provides Insight into Mold Market

The Committee for Equipment Statistics of the Society of the Plastics Industry has started to compile and report data on the market for hot runners. This is a new data set, so the amount of statistical analysis that can be performed is limited. But the trend in market demand for hot runners should ultimately prove quite interesting to moldmakers.

The Committee for Equipment Statistics of the Society of the Plastics Industry has started to compile and report data on the market for hot runners. This is a new data set, so the amount of statistical analysis that can be performed is limited. But the trend in market demand for hot runners should ultimately prove quite interesting to moldmakers. More data is always better than less. With that in mind, here is my analysis and forecast of the hot runner data.

In the fourth quarter of 2012, the data for hot runner demand suffered a disconcerting drop of 23% from the total booked in the third quarter of this year, and it was down 15% when compared with the total from the fourth quarter of 2011. For 2012 as a whole, hot runner bookings gained 2% when compared with the total from 2011.

Despite the precipitous drop in the number of units ordered, the total dollar value for new bookings in Q4 of 2012 escalated by 7% when compared with Q3 of this year. The Q4 dollars total represented a gain of 14% when compared with the same period of last year. For the annual total in 2012, the value of hot runner bookings was up by a solid 22% when compared with the annual total from 2011.

The end-market breakdown for Q4 shows that most categories were down in terms of units from year-ago levels. Automotive declined by 11%, packaging dropped by 16%, and medical was off by 20% when compared with Q4 of 2011.

The forecast for this market calls for continued growth in hot runner demand in 2013 when compared with 2012, but the strongest gains will occur during the second half of this year. The first half of 2013 is expected to be steady-to-down. The growth rate will decelerate because the historical comparisons will be more difficult this year. In 2013, look for a gain of 5%-6% in the number of units ordered, and an increase of 8% in the dollars total.

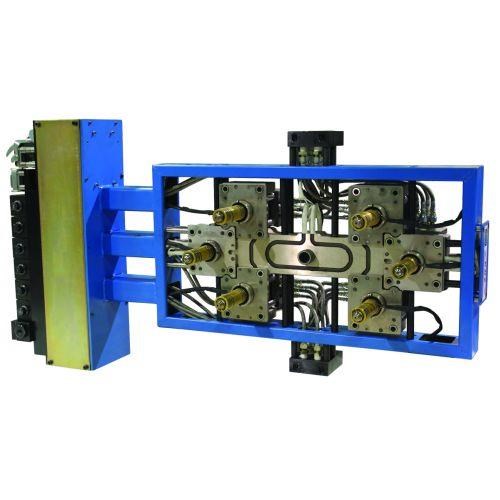

Photo courtesy of DME.

Related Content

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

.jpg;maxWidth=970;quality=90)