"Form"ing the "Next" Generation of Advanced Technology

With the premiere of Formnext, Frankfurt Germany's additive manufacturing and tool making event, just around the corner, I thought I'd share a little Q&A I had with the event's vice president Sascha Wenzler when he toured the United States earlier this fall.

With the premiere of Formnext, Frankfurt Germany's additive manufacturing and tool making event, just around the corner on November 17-20, I thought I'd share a little Q&A I had with the event's vice president Sascha F. Wenzler when he toured the United States earlier this fall.

MMT: What is the goal for FormNext?

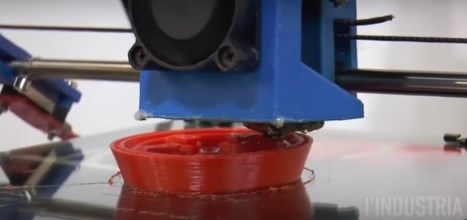

FormNext: We want to provide attendees with an information platform that illustrates how the interplay between additive technologies and conventional procedures opens up entirely new possibilities in product development and manufacturing.

MMT: How many exhibitors are there so far?

FN: We have 228 exhibitors are registered.

MMT: How did the industry react at the announcement of this event?

FN: It’s worth mentioning that it was the considerable demand from the industry that provided the impetus for developing Formnext. Many exhibitors were keen to retain the international exhibition grounds in Frankfurt am Main. Formnext didn’t just happen – it was and still is an evolutionary process.

MMT: What will take place during the event?

FN: Together with our partner TCT, we have a high-profile conference that will run in tandem with the exhibition. Since 1992, TCT has been working on connecting additive manufacturing industries and developers and engineers from all industries. The conference will be held in English and German with simultaneous interpreting.

On all four days of the exhibition, the conference will highlight cutting-edge technologies and applications in additive technologies and explain how they are influencing product development and production. We have keynotes from Audi, EOS and Stratasys, as well as around 30 international speakers for the conference. Also, as one of the world’s leading automobile manufacturers, AUDI AG will showcase a special exhibit on toolmaking. Audi Toolmaking” will take attendees on a journey through the history of toolmaking at Audi to current production techniques, including the latest trends in product development and a look at Industry 4.0. It will also demonstrate how generative technology is becoming part of toolmaking at Audi and what opportunities this technology offers.

For more details click here.

Related Content

-

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

-

Mold Builder Uses Metal 3D Printing to Bridge Medical Product Development to Production

Westminster Tool uses metal additive manufacturing for medical device OEM, taking lessons learned from R&D in the prototype mold phase to full-scale production molding in a fraction of the time.

-

How to Make Data Work for Mold Productivity and Performance

The use of digital workflows improves the impact of mold design libraries, conformal cooling and machine learning.