Did You Say "Prototypes Out of Paper"?

No, this isn't a late post celebrating Halloween, but it will surprise you. It's actually highlighting a technology that may just help you get into 3D printing, if you have been searching for a method that is not cost-prohibitive. Last month I spent four days in Frankfurt, Germany walking the halls of Euromold--the world fair for moldmaking and tooling, design and application development--and one particular technology caught my eye: a low-cost, eco-friendly, 3D printer that builds durable physical models from common letter paper.

No, this isn't a late post celebrating Halloween, but it will surprise you. It's actually highlighting a technology that may just help you get into 3D printing, if you have been searching for a method that is not cost-prohibitive.

Late last month I spent four days in Frankfurt, Germany walking the halls of Euromold--the world fair for moldmaking and tooling, design and application development--and one particular technology caught my eye: a low-cost, eco-friendly, 3D printer that builds durable physical models from common letter paper.

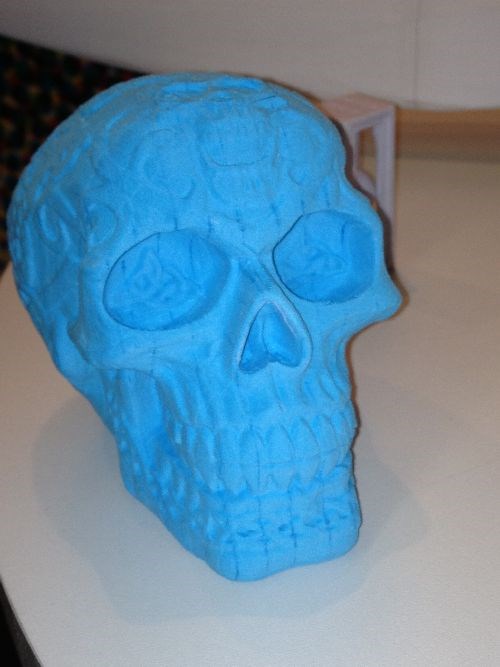

Ireland-based Mcor showcased its full-color Mcor IRIS and its monochrome Mcor Matrix 300+ systems, which according to the company are the only 3D printers that create physical models from new or used standard letter paper, whose resulting model is durable. This can be used for the production of prototypes and mold tools.

So although you may have thought I was in Germany sipping Glühwein, strolling through the Christkindlmarkt and chomping on some Brätwurst, I was actually seeking out technology over there that can be useful to shops back home. Stay tuned as I post more information on other technologies, but in the meantime check it out.

Related Content

-

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

-

MMT Chats: 5 in 5 with Best Tool and Engineering

MoldMaking Technology Editorial Director Christina Fuges reveals 5 best practices for improving efficiencies within shops...in 5 minutes. Our guest is Joe Cherluck, President of Best Tool and Engineering in Clinton Township, Michigan.

-

Confronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.