Published

"Cool" Tool

With all the coverage of conformal cooling, what if a smart processing tool could help to optimize the cooling efficiency of your molding process? Take a look at this cooling channel designer.

With all the discussion about conformal cooling, everyone is looking to enhance its design to optimize heat dissipation and achieve uniform cooling, as well as to improve product quality and reduce cycle times and costs. Here is just one tool that claims to help with these goals. Moldex3D partnered with One Process Machining (OPM) laboratory in Japan to develop a simulation tool for conformal cooling through which users can "build conformal cooling channels according to the contour of a product in a fast and intuitive way."

According to Moldex3D, mold designers are then able to change the cooling design to make cooling channels closer to the molded products in the cavity, so the temperature can be more evenly distributed. This helps eliminate cold and hot spots inside the mold, minimizing residual stress, warpage, voids and sink marks.

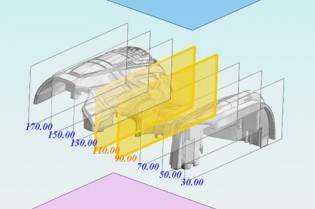

One interesting feature is a “slicing” function that allows users to slice up the imported part into several sections, easing and improving conformal cooling system design, according to the company. In addition, cooling analysis predicts the required cooling time, shows temperature variation inside the mold cavity and can predict coolant flow rate, pressure loss and vortex/dead water areas.