Build-Ups for Maintenance: Benefit or Band-Aid?

When is providing build-ups on tooling appropriate and when is it just a band-aid on a problem that could lead to more extensive repairs later?

One maintenance issue that often creeps up is the request for build-ups to replace missing steel or other metals on tooling. The most common reasons for using build-ups is in the repair of worn or mis-machined components, and the desire to reduce wall stock as a cost-saving measure. Everyone is trying to save money, but when is providing build-ups on tooling appropriate and when is it just a band-aid on a problem that could lead to more extensive repairs later? The application of a build-up is highly dependent upon the information shared between the customer and plating vendor.

What’s in a Build-Up?

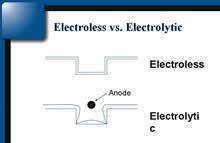

When a build-up is created, it is done using either electroless or electrolytic nickel or hard chrome (see Figure 1). The desired thickness of the build-up helps determine which of these is most appropriate.

Masking off the entire piece and isolating the area for heavy accumulation can be very labor intensive. Hard chrome shims and inside and outside diameter corrections are common up to 0.030 of an inch in thickness. However, hard chrome plating over 0.001 is not typically held to size due to slight variations in thickness that can occur. The result is often a slightly thicker coverage on outside corners while the inside gets slightly less, so of course it almost always requires grinding or EDM to size after plating.

Pre-Engineered Build-Ups

At 72 Rockwell hardness, hard chrome build-ups are commonly built into new tools to protect high wear areas, such as bearing surfaces on rotating cores, slides and lifters, to eliminate galling. Use caution, however, when running a chrome build-up against another surface. It would be wise to have an optimal 6 to 8 Rockwell difference in hardness between the metals to prevent galling. Running two surfaces of the same hardness can cause flare-ups because neither material will break down against the other.

Many times, with mating surfaces such as cores and sleeves, knowing which surface gets a certain coating can help eliminate problems. It is prudent to discuss the options with your plating vendor.

The Many Faces of Nickel

Another choice is electroless nickel, which is commonly used to plate tooling to size up to 0.003 P/S. Unlike hard chrome, when electroless nickel is applied it goes on very uniformly.

With a Rockwell hardness of 50, electroless nickel is often used to correct the size of threads on cores and slide details. Electroless nickel, with a phosphorous content of 11 percent or greater, can be used for build-ups and also to create a diamond-turned, mirrored finish for molding optical lenses. In addition, a heavy build-up of electroless nickel on cores and cavities can effectively displace plastic, as when a change in the molded material is made and it affects part shrinkage.

Sulfamate Nickel

Electrolytic sulfamate nickel is excellent for heavy build-ups as well as salvage of tooling (see Figure 2). It can be deposited in thicknesses in excess of 0.200 with minimal inclusions and is a good alternative to hard chrome in certain heavy build-up cases because it is softer, at 40 Rockwell hardness.

Sulfamate nickel, which is very easily machined, is also ideal for heavy, uniform build-ups and is generally used when more than 0.030 thickness is required. In fact, sulfamate nickel can plate in excess of 0.200 and can be cut or turned to size.

Threaded Dilemma

If build-ups are requested for threaded applications, there are some factors that need to be considered before moving forward. Threads can be plated, but electroless nickel, which plates uniformly, must be used. Also, because re-machining threads is not desirable, a maximum deposit of 0.005 P/S is normal while maintaining the integrity of the part.

Other Options

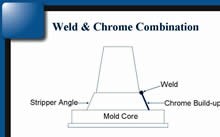

Welding, in particular micro TIG welding, may also be an appropriate alternative to build-ups, such as when a very delicate, small corner is in need of a build-up for repair. Welding can also be effective when used in tandem with hard chrome (see Figure 3). First, a weld is applied to the corner of the substrate being plated, and then chrome is applied. Both are then ground in the same operation. The steel weld deposit will protect the lead edge and the chrome from chipping. If a micro weld is used, there is less heat involved and therefore less chance of compromising the integrity of the part.

Build-ups can also be used to correct the location of holes in multi-cavity tooling. Using hard chrome, the inside diameter is reinforced with the build-up and then the hole is jig ground back into the correct location. If a permanent fix is required, the hole should be opened up before the build-up to allow for even grinding to the final size.

In cases where time is a major factor, another option might be the use of diamond chrome in place of hard chrome. At a sturdy 85-plus Rockwell hardness, it requires less of a deposit, but offers increased hardness that can be plated to size, from 0.0001 to 0.0006 P/S, with no need for grinding.

Finally, to avoid downtime, use caution when using build-ups on pre-loaded shut-offs plated with heavy deposits. These are susceptible to fracturing or cracking and it’s then that you’ll find that these types of build-ups are best avoided.

In closing, it is wise to share information, prints, pictures and piece parts with your plating vendor. Together, a successful completion of a difficult project is attainable.

Related Content

Breaking Down 3D Scanning in Moldmaking

Identifying 3D scanning requirements and implementing the appropriate technology.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

Coatings Enhance Tool Life and Performance

Surface coatings have evolved over the past decade—offering improved operation uptime, greater consistency and higher part quality

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More