Advanced Prototyping for Threaded Parts

A look at a modular tooling standard designed to help cost effectively develop caps and closures to be either stripped out of the mold or use a collapsible core.

It’s just a cap, so how hard can it be, right? Those in the industry know well that it’s not making a cap that’s hard; it’s making millions of caps while managing the needs of manufacturing, accounting and sales departments. It’s a competitive market looking for efficient production at a low price with unique marketable aesthetics and features. Balancing all of this is the challenge of product development in the cap and closure industry.

Because of these demands, R&D in this market is very important. Before capital can be spent and lead customers gathered, a concept has to be tested to prove out manufacturability, cost and market acceptance. Since there is no guarantee the product will go to production, development costs are kept as low as possible. To keep tooling costs down, inexpensive tooling is usually used, which allows for part analysis, but does not allow one to determine the true manufacturing costs. In addition, alternate tooling approaches are often ignored as companies focus on traditional methods up front, leaving little to no chance of analyzing options that may reduce costs in production.

Conventional Prototype Tooling

Prototype molds are a key contributor to this development process. Most prototype molds are done as inexpensively as possible to prove out the concept and get samples that can be shown to potential customers. However, these molds often aren’t capable of running automatically and so options like hand unscrewing are used, which allows little, if any, opportunity to learn production expectations.

Pilot of unit molds are also commonly used in development. These molds are more expensive, and are intended to demonstrate production capabilities and run fully automatic. They are not as common because of the higher up-front capital cost.

Both of these styles of tooling are usually done as single-cavity molds, which is fine—until a project is approved for production and larger volumes are required for line trials and auxiliary equipment builds. Since they are single-cavity molds, the piece part cost is high and running larger volumes is very time consuming.

An Alternate Option

Many closures fall within a similar diameter and height range, and they utilize common tooling methods. Yet, there is no standard system available that allows for testing those tooling options head to head.

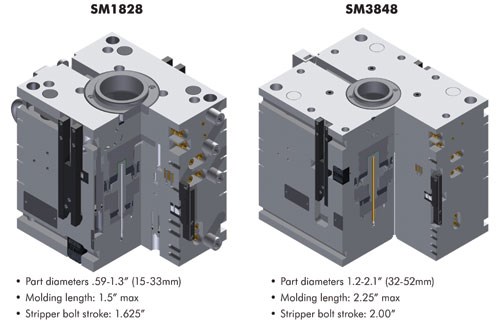

As a result, companies have a tendency to stick with what they’ve always done during development and that tends to carry right on through to production tooling. This means options like collapsing cores, which could bring cost savings in production, are often overlooked. So, a new approach to cap and closure development is available in the form of a pre-engineered, modular tooling standard that’s designed for customers to cost effectively develop caps and closures to be either stripped out of the mold or utilize a collapsible core (see Figure 1).

These molds offer the low cost of a prototype mold combined with the production capability of a pilot mold. It’s a four-cavity, production quality mold designed to be modular. By swapping out inserts, the mold can be converted to run different parts within the same mold frame. A single cavity “proto” can be utilized during initial trials and if the project is successful, the additional three cavity stacks can be completed taking you to a four-cavity pre-production or “bridge” mold. When R&D is completed, the mold can be returned to the toolroom and is ready to use for other product development (see Figure 2).

Tooling Comparison

A common question asked during development is “Can I strip this cap out of the mold?” It is the least expensive production tooling option, so it’s often preferred. However, there are limitations to undercut depth and profile. Part ejection puts a large stress on the part, which can result in rejects like undercut damage and ovality issues—in addition to mold issues from the high ejection pressures required. A collapsible core may help resolve some of these issues and actually reduce cycle time. By using a pre-engineered, modular tooling standard, both techniques could be tested within the same mold frame and then numbers can be run to determine which makes the best financial sense in the long term for production.

Summary

To balance the demanding needs of the cap and closure industry, product development teams need many tools in their toolbox. By utilizing a system like a pre-engineered, modular tooling standard, development time and costs can be kept low and production capabilities can be learned.

Related Content

Compact Robotic Palletizer Easily Automates Packaging Process

The Cube cell, complete with a KUKA KR50-R2500 robot, is targeted for small- and medium-sized businesses looking to automate the palletization of their end product.

Read MoreHow Hybrid Tooling Accelerates Product Development, Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read MoreHow to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreInnovative Mold Building Enhances Packaging Material Efficiency, Elevates Recyclable Design

A manufacturing-focused design and optimized tooling enhance material efficiency in packaging for a new medical instrument.

Read MoreRead Next

Justifying a Mold Rebuild Using Collapsible Core Technology

Technical advantages prove there is ample reason to explore rebuilding—or retrofitting—traditional unscrewing tools.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More