A Sticky Situation: What Surface Treatment Do I Really Need?

Over the years, and more times than can probably be counted, customers call from all over to order various surface treatments for their molds, without knowing what is truly needed to make their molds run better and more efficiently.

Over the years, and more times than can probably be counted, customers call from all over to order various surface treatments for their molds, without knowing what is truly needed to make their molds run better and more efficiently. It’s surprising how many customers are talked down on services because it’s not good business to oversell someone and risk losing their trust; but it is good business to try to educate them.

Every day molds are delivered for service with inadequate or no documentation. There are so many unknowns, which leads to a lot of chasing and unproductive delays that cost money. Be sure to provide the following details to your polishing and plating vendor:

- Steel type (base material)

- Coating being requested

- Amount of coating deposit required

- Finish required and any masking requirements

- Any issues or objectives (i.e., abrasion or corrosion protection, better release, a combination or something else)

Unfortunately, not only are jobs arriving without good documentation, they are arriving last-minute, in rush mode, turning the situation into a rescue mission rather than what it should be: a well-planned and proactive solution. Rush jobs almost always turn into over-compensation and they can be costly.

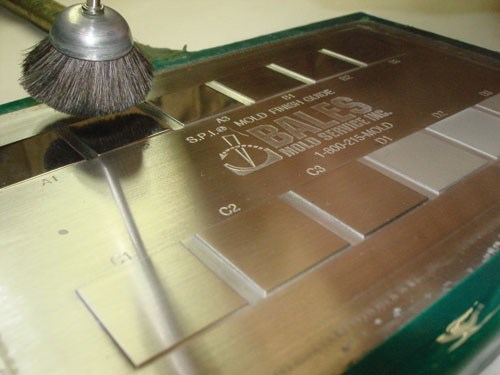

For example, the three stages of a diamond finish are very different. An A-1 diamond is three to four times more labor intensive—more expensive—than an A-3 diamond. If the part is not decorative and does not need to be clear and optical then why spend the extra money? Don’t mistake an A-1’s “shiny” appearance with good release. Instead consider more cost-effective options like an A-3, or a light, low-pressure bead blast for a microscopic finish that promotes good release.

Another cost-cutting measure has to do with masking. Masking is a painted wax-like material used to protect areas of a mold from being plated. It takes time to apply because each layer of masking must dry before another is applied. The larger the plating deposit, the more masking is needed. The mold must also be unmasked after plating. In some cases, it’s faster and more economical not to mask (especially in non-critical areas) and plate the whole mold if using nickel or, if using chrome, let the plating material bleed over and then the mold shop can grind the 0.0002- 0.0003” off.

With the industry and economy still recovering, it pays to do the homework, ask the questions early on in the project, and provide as much information about the tooling as possible. A qualified vendor can then help determine the best, most economical solution.