A Modern Moldmaking Trend

Moldmakers continue to pursue adding processing capabilities—whether for sampling or production molding. One shop’s journey spells out all the required investments.

Moldmaking can be a difficult business to accurately forecast. Work comes in when the OEM/brand owner is ready, and the ability to impact the project launch is out of the hands of the tool shop. The lure of growing a tooling business by expanding into custom production molding is one that has attracted and continues to attract many tool-shop owners. Having a revenue stream built on the production of a planned number of components certainly sounds like a much easier way of making a living. However, competing and performing successfully as a production molder requires a great deal more than simply purchasing injection molding machines, then putting pellets in one end and counting the money that comes out the other.

Certainly, one of the largest expenses is the equipment and expanded facilities required for the job. All modern tool shops understand the cost of high-performance machining technologies. On the shop floor, high speed, high precision and high repeatability all come with a high price tag.

The cost of the equipment required for production molding is not necessarily a barrier to entry, as most tool-shop owners generally make five- and six-figure investments for machine tool technologies. A very significant challenge is the cost and time needed to attract and develop a new set of talent. Just like on the tool-shop floor, where experienced and skilled journeymen are critical to success, the molding floor requires engineering disciplines, including process engineers, quality system administrators, mold setup technicians, material handlers, press operators and equipment maintenance personnel.

In addition, production molding also requires a significant investment in facility space—room for molding, assembly and value-added operations; space to store and dry the resins; warehouse real estate to store the product prior to shipment; and so on. That leaves the tool shop with two choices: either buy an existing molding operation or develop one on its own. Here, we discuss the latter scenario.

Growing with a Plan

Oftentimes, the tool shop looking to grow into custom molding is one that is likely already dealing with a mix of customers—certainly the OEM/brand owner—and that appears to make the decision a logical one. For the shop whose long-time customer base is primarily comprised of custom molders, there very well may be (and perhaps should be) a reluctance to compete directly with the source of its core business revenues.

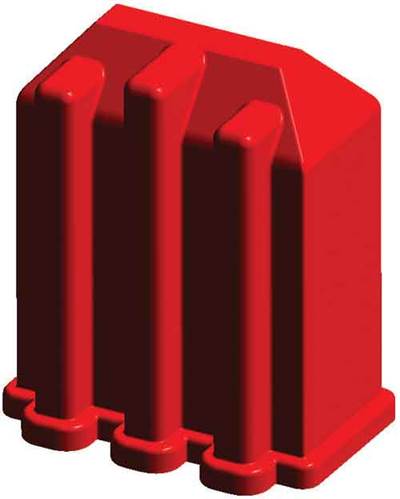

The events and decisions behind MGS Mfg. Group’s expansion into production injection molding are both typical and atypical. Company founder Mark Sellers deliberately crafted his company and team with a proactive mind-set with regard to mold engineering and design. From its beginning in 1982 as Moldmakers Inc., MGS Manufacturing Group sought opportunities to build tooling systems that could handle challenging part geometries. Injection molds featuring multiple actions, tight tolerances, multiple plates, hot runners, auto-unscrewing features, collapsible cores, highly polished surfaces and/or multiple component/multishot capabilities with aggressive lead times were all in the shop’s wheelhouse. Within 10 years, it grew from a handful of toolmakers working out of a leased garage-size shop to a company of more than 40 moldmakers, designers and engineers. By 1992, the company had finished its third expansion of the facility it owned in Menomonee Falls, Wisconsin, and had established a solid reputation as a go-to shop for tough projects.

There are few passive tool-shop owners—most are toolmakers, after all. To be a great toolmaker requires a keen mind and a high level of self-confidence, because that is what it takes to be a problem-solver. Sellers and his crew were no different. When a challenging project came their way, they met it with innovative engineering and sophisticated techniques. These methods often brought resistance from the destination molder, who had no interest, for example, in running multishot molds that required specialty molding equipment, or in running molds with more than a half-dozen actions that needed a higher

level of operational expertise and demanded more frequent, sophisticated preventive maintenance.

The plastics business landscape was a different animal 30 years ago. For the most part, OEMs (those without internal injection molding capabilities) regularly worked through their sources of part supply, leaving the decision of tooling strategy

to the chosen custom molders. The tool shop did not have direct contact with the OEM, and the tooling concept was primarily driven by what best suited the existing capacities and technical capabilities of the molder.

This was certainly not always a negative, however it did preclude the OEM from being exposed to and considering alternative tooling and molding concepts. By the early ‘90s, many OEMs were going direct to the tooling source, driving a focus on production through upfront engineering. This was especially true of companies whose product line’s success was based heavily on speed to market, such as telecommunication devices, computer accessories and storage, and other retail-based consumer items.

Sampling Strategy

MGS’ mission had always been to deliver quality molds with improved functionality. In early 1993, as part of an effort to increase service to both OEMs and custom molders, the company decided to dedicate resources to directly manage tool functional samples as an integrated part of the mold build. Up to this point, the shop had relied on outsourcing the sampling phase of a project.

Sellers realized the biggest hurdle to managing sampling in house was not the investment in molding assets but the acquisition of talent. The company first found an individual with extensive molding experience and an entrepreneurial desire at a customer. Next came the search for a few process engineers/technicians. Fortunately, the plastics industry had and continues to have a very large presence in Wisconsin’s manufacturing community. When word spread that MGS was looking for self-starters to drive a new company within a company, several key individuals emerged and were hired to be part of this new venture.

The new sampling team began developing the systems, procedures and documentation required to properly evaluate, analyze and optimize MGS injection molds. Rather than make an immediate investment in a new facility and injection molding machines in an appropriate tonnage range, the company continued to rent machine time at a variety of local custom molders. The sampling team earned its chops by working with a variety of tooling customers on a wide range of old and new equipment. The group’s experience level grew quickly, and lead times for product launches were greatly reduced by eliminating the non-productive time an injection mold spent on the truck traveling from the production molding facility to the tool shop and sometimes back to the molding facility when steel adjustments were required.

Bringing it in House

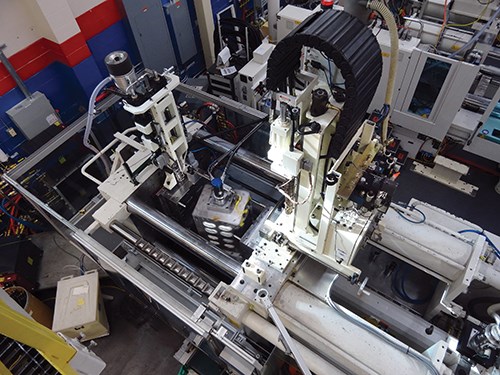

In 1994, MGS leased a nearby 5,000-square-foot facility and purchased four new injection molding machines ranging from 90 to 390 tons, as well as multiple-capability Matsui hoppers/dryers, air-cooled chiller systems and water temperature controllers. Although sampling capabilities were now in-house, the shop still needed to continue to use some outside resources as tooling output and revenues continued to increase each year.

Before it had access to injection molding machines, the shop would assemble a mold and ship it to a custom molder for a trial run. Mold functional sampling typically includes evaluating choices for gating location and size, venting, and shutoffs; verifying that fluid passages (hydraulics, water and pneumatics) are properly sealed, basic part fill and integrity, and that there are no anomalies with regard to mold flow; and validating that the ejection system is performing properly. MGS toolmakers say that, before they were directly involved in mold functional sampling, they were unaware of the many adjustments and corrections a molder might have to make to bring a tooling system to production-ready status. An injection mold on the tool-shop bench behaves very differently once it is mounted into an injection molding machine and heated. For example, tightly seated slides that function well on the bench react quite differently under the heats and pressures of the production molding environment. The team quickly learned that mold-build strategies can only be properly evaluated after the mold has progressed through several hundred or even thousands of injection cycles.

Part measurement at this phase of the project can determine a need for steel adjustments, which can delay product launch. But a tool shop that has immediate access to the sampling press is in a position to respond quickly and efficiently.

Sampling Success

With a dedicated staff, equipment and facility, MGS’ sampling services proved their worth in relatively short order. Custom molders valued having production-ready molds delivered to them without tying up their own resources. The OEM customer base responded with a continuing flow of work and also began engaging the company’s engineers and designers earlier in their projects. Instead of simply being one of its customers’ tooling sources, MGS became a development partner, supplying engineering, consultation, desig for manufacture, prototyping, proof-of-performance tooling and production molds. Invariably, in several cases, this led to opportunities for “keeping it in the press.”

Once the company was able to demonstrate that a mold was qualified to produce production-validated products, the mold owner wanted parts. In some instances, this was to create inventory to support sales during mold transfer to the production molder. In other cases, it was because the OEM’s sales channel was open, and every day without product meant lost revenues. Although it was not necessarily part of its original plan, MGS had begun offering services that normally could only be found at a custom molder.

This led the company to increase capacity for sampling, molding and tooling, as opportunities for one brought opportunities for the others. Any sampling press that was being used to produce qualified products could not be used as a testing instrument. Having custom molding capabilities required a great deal more floor space for additional presses, material, packaging and finished-inventory storage, and a larger dedicated staff of process engineers, mold setup techs, material handlers, press operators, shipping/receiving staff and project managers.

In 1995, the company built the MGS Tech Center in Germantown, Wisconsin, a 60,000-square-foot facility with space for additional toolmaking, administration, and

sampling/debug/qualification and production molding.

Mixing in Custom Molding

For many in the plastics industry, the mid-to-late–‘90s were a time of explosive growth. While there had always been some appreciable level of competition from abroad, many of the biggest brand owners made their products in North America. Business opportunities for build-and-run projects were so good at the time that, within a year after operations began at the Tech Center, MGS started building its third facility, an 80,000-square-foot plant dedicated to custom molding.

TecStar Mfg. Co. formally opened its doors in 1997, and by that time the MGS Mfg. Group had defined itself as a vertically integrated, single-source supply partner. Within one year of launching a dedicated molding facility, the tool shop’s reputed prowess at building multishot molds had led to many opportunities as a multiple-component production molder for the telecommunications, automotive, appliance and consumer markets. These opportunities also drove the company into specialty molding equipment construction, creating the Universal Multishot Systems brand name to identify its portable injection units and rotary systems for multiple material production. This led to more tooling, sampling and molding work, which led to further facilities expansion and acquisitions over the last 14 years.

Taking Risks and Reaping Rewards

One thing truly can lead to another, especially for those with the entrepreneurial foresight and risk-taking mind-set to recognize opportunities and be decisive about actions. Ask Mark Sellers how MGS did it, and he will laugh and tell you, “We didn’t know we couldn’t!” The key word in his answer is “we.” Sellers says the success and growth of MGS is not because of strategic investments in equipment or facilities, but because of the people behind those decisions and the persons responsible for carrying them out. Without the right people, none of this would have been possible, he says.

The tool-shop owner looking to grow significantly in the next five, 10 and 20 years, whether or not molding is in his future, might want to consider looking inward first. What kind of team do you have now, and what kind of team will you need? Anyone with a line of credit can buy equipment. Successful people make things happen by pushing the right buttons at the right time.

Related Content

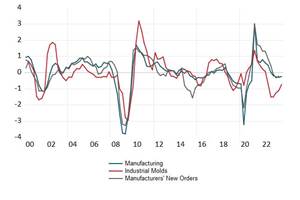

Navigating Economic Resilience and Consumer Trends

Consumer behavior provides mold builders insight into the evolving market dynamics of goods and services that helps strategic planning.

Read MoreInternational Partnership Improves IBM Preform Precision

Hammonton Mold Co. and ADOP France team up to bring injection blow mold preform design and service to the next level.

Read MoreHow Hybrid Tooling Accelerates Product Development, Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read MoreMMT Chats: Digitalizing Mold Lifecycle and Process Performance

MMT catches up with Editorial Advisory Board member Bob VanCoillie senior manager of Kenvue’s mold management center of excellence outside of Philadelphia to discuss mold management via tooling digitalization and OEM expectations and opportunities.

Read MoreRead Next

Mold Cleaning Done Right Takes a Systematic Approach

Mold cleaning is just one part of a systematic and comprehensive approach to mold maintenance. Here’s one moldmaker’s strategy for injection mold cleaning and an explanation of where and why different techniques are employed.

Read MoreCooling Technology for Cycle Efficiency

A 3D simulation study helps quantify the effects of mold cooling design choices on cycle cooling time, which moldmakers can then use to make smarter design cost versus part production cost decisions at the earliest possible tool design stage.

Read MoreMGS Mfg. Group: Sampling Success

A foray into sampling led this toolmaker to design its own multi-shot tooling system and equipment.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)