Supply Chain

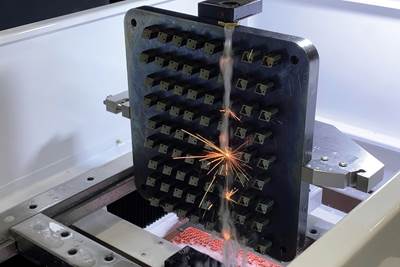

2022 Sourcing & Technology Guide: EDM

EDM refers to wire, sinker and small-hole electrical discharge machining. Components include drives, generators, programming, flushing, wires, electrodes, graphite, filters and fluids.

Read More2022 Sourcing & Technology Guide: Additive Manufacturing

3D printing, or additive manufacturing, simplifies the moldmaking process by making mold inserts, mold components, end-use parts and ancillary equipment.

Read More2022 Sourcing & Technology Guide: Mold Components

Mold components make the mold work and the mechanisms used to deliver a quality end product. Key components include mold bases, pins, ejectors, lifters, bushings, guides and alignment devices.

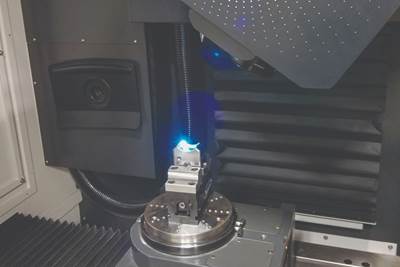

Read More2022 Sourcing & Technology Guide: Software

Design and engineering are essential to building a better and more cost-effective mold with shorter lead times. A variety of software is available to help overcome the daily challenges faced with data, quoting, designing and programming.

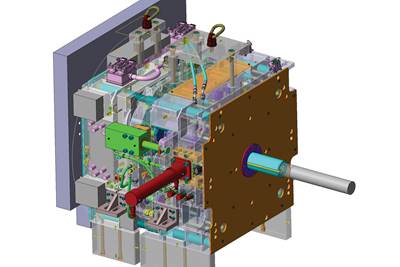

Read More2022 Sourcing & Technology Guide: Mold Builders

A variety of processes are used to engineer, build, maintain, repair and manage a mold, which can be offered as standalone services to be contracted to complete a mold build—from design and machining to tryout and welding.

Read MoreYour 2022 Technology Review and Sourcing Guide

MoldMaking Technology’s annual Technology Review and Sourcing Guide streamlines the search for new products, equipment and services with updated supplier listings alongside product and service reviews.

Read More2022 Sourcing & Technology Guide: Mold Maintenance, Repair and Surface Treatment

A proactive maintenance plan to properly treat a mold to keep it running will decrease repair costs. Proper treatment of the mold’s surface is key to quality, corrosion-resistance, wear and tool life.

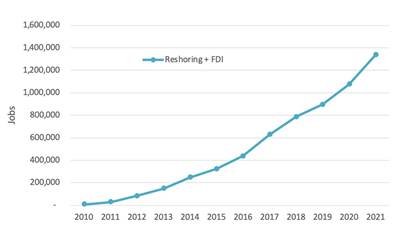

Read MoreReshoring Initiative Releases 2021 Data Report

For the second year in a row, reshoring exceeded foreign direct investment job announcements by 100%, according to the report.

Read MoreMold in a Day Technology Slashes Tool Production, Eliminates Supply Chain Headache

Next Chapter Manufacturing says its Mold in a Day additive manufacturing technology slashes the production of tooling down to hours while maintaining the same quality and tolerance standards of conventional molds.

Read MoreHarbour Reports Tooling Industry Growth Despite Challenges

The Q1 2022 Harbour IQ Manufacturing Pulse Study indicates that the tooling industry rebounded in 2021, with companies seeing year-over-year revenue growth.

Read More