Mold Materials

MMT Chats: 30 Under 30 Honoree, Project Engineer & Lean Six Sigma Rep Shares Passion

MoldMaking Technology Editorial Director Christina Fuges brings on EDRO Specialty Steels Project Engineer Katherine Pistorius as a guest for this MMT Chats video interview to talk about her love of cutting waste, process management, and efficiency, which lead her to Lean Six Sigma. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

WatchEllwood Specialty Steel Introduces Improved Lens/Texture-Quality Mold Steel

Amerimold 2021 exhibitor Ellwood Speciality Steel’s P20-modified, through-hardened mold steel boasts a consistent surface finish, and is fully qualified to GMQ 18157 mold steel specification.

Read MoreMicro-Milling Improves Steel Plate Quality, Saving Mold Building Time

Reed City Group switches to steel plate that is flatter, more dimensionally accurate and cuts 10-15% off tool-building time.

Read MoreFrom CAM, Cutters and Cooling to Corrosion, Cleaning and Control

A review of the year’s top tips on technologies and strategies to improve moldmaking operations from design to first shot.

Read MoreInjection Mold Machined Plates Boost Flexibility

Hasco’s P1 plates, machined on all sides, come in about 2000 additional variants in dimensions, thicknesses and materials.

Read MoreSteel Plate Manufacturing Process Enables Easier, More Accurate Installation of Components

Steel 21’s patented process for manufacturing flat and parallel steel plates, 21 Micro Milling, holds A36/4140 grade steel plates on average 3 times more flat and parallel and 5 times smoother.

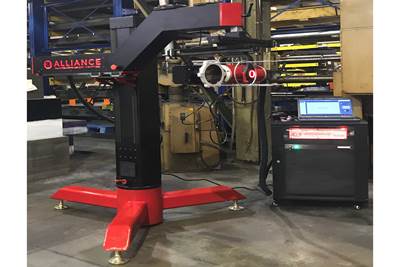

Read MoreExpanded Service Capabilities Include Tool Steel Laser Engraving

International Mold Steel’s laser engraving service is offered in-house at a reasonable price.

Read MoreUsing the Right Technology at the Right Time and in the Right Way

Michigan mold and die maker puts its engineering expertise to work for each customer.

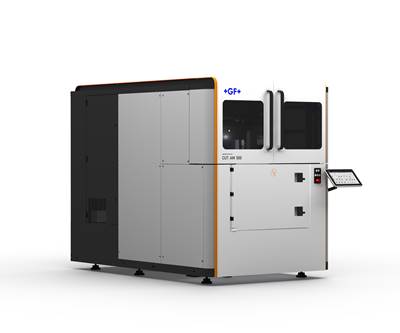

Read MoreEDM Speeds Up Additive Part Separation, Preserves Part Integrity

GF Machining Solutions announces the AgieCharmilles Cut AM 500, a horizontal wire EDM designed to complement metal additive manufacturing.

Read MoreDie-Sinking EDM Optimizes Micromachining Processes

GF Machining Solutions showcases the AgieCharmilles Form X 400 die-sinking EDM solution.

Read More

.jpg;maxWidth=300;quality=90)