Mold Materials

Efficient Machining of Micro EDM Electrodes

To achieve efficiency and quality in machining micro EDM electrodes, consider a machine dedicated to this process.

Read MoreAdvance Wire EDM

The series combines the high speed of the V machine with the FA-S’s high accuracy and surface finish.

Read MoreReinvesting in Machinery, Processes and People Adds to Bottom Line

Specializing in high precision molds with interchangeable components, RMM has supplied the industry with a wide variety of tools including, single face, stack, unscrewing, multi-material, rotary cube technologies—and considers its customers’ needs a number-one priority.

Read MoreTexturing Molds for Thermoplastics: Factors for Success

Factors to consider when selecting a texture or grain for a thermoplastic mold or die.

Read MoreCutting Tool Slashes Cycle Times by 75 Percent

This moldmaker reduces cycle times from 10 hours to two hours with a more durable, faster cutter that also leaves a nice finish.

Read MoreOptimize Machine Performance with Proper Filtration

There are multiple factors to consider when it comes to operating a wire EDM and filter quality should be one of them. Proper filtration can save EDM users money and time relating to production and maintenance. Buying low-cost filters may seem like an easy place to cut costs, but the truth is, it can be a costly mistake.

Read MoreBeating Business Volatility in Automotive Tooling

Constant-velocity cutting offers low-cost, high-tech option to hand finishing EDM electrodes.

Read MoreHow Trends in Diesinking EDM are Benefiting Moldmakers

Turnkey solutions that provide automation in a more affordable and easy-to-implement package are available for today’s mold manufacturers.

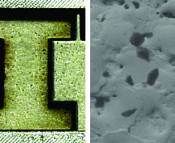

Read MoreElectrode Effect on a Quality EDM Finish

The production of fine surface finishes in the cavity does not come with the technological improvements of the EDM sinker unless an electrode material of higher quality is used.

Read MoreIncorporating Automation into Your EDM Drilling Operation

Every shop that uses EDM drilling technology is a prime candidate for automation. Some just don’t know it yet.

Read More

.jpg;maxWidth=300;quality=90)