Mold Materials

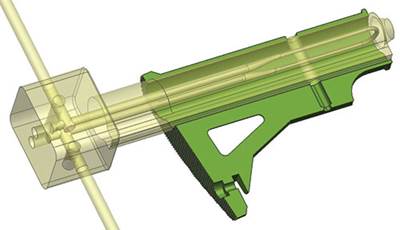

The Intersection of Laser Sintering and EDM

For this moldmaker, wire EDM helps streamline production of inserts that are “grown” with cooling lines already inside.

Read MoreFrom Craft to Science

For this shop, efforts to adapt to technology that reduces the need for human labor have driven a fundamental and ongoing shift to a more standardized manufacturing process.

Read MoreGoing to Extremes with EDM Drilling

Expertise in drilling start holes helps this wire EDM shop give 110 percent on every job without breaking the bank.

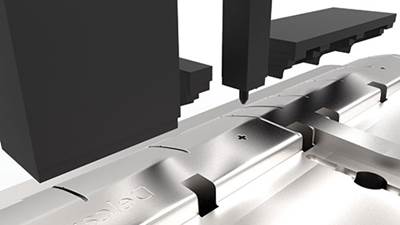

Read MoreImprove and Simplify Wire EDM

A CAD/CAM system with dedicated wire EDM functionality should allow the user to select a specific machine from within the system and apply the conditions to the machining operations.

Read MoreLet’s Be Clear About Aluminum

Within the injection molding industry, a negative perception of aluminum for anything but prototype plastic parts persists, despite aluminum tooling being able to produce and run almost any resin that steel can, as well as produce millions of shots with unfilled resin with uniform results.

Read MoreWire EDM Goes 3D CAM for Moldmaking Operations

New features, technologies and software make wire EDM well-suited for tackling solid models, and improving taper angles and surface finish.

WatchThink Metric, Part 3

Insight from several technology suppliers—in design software, mold components, programming, machines, cutting tools and measurement equipment who have been following the metric trend—may help to make the transition a smooth one.

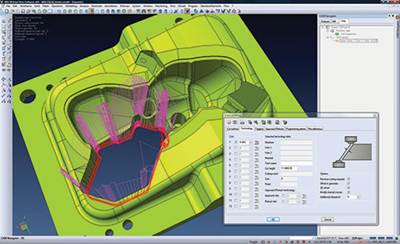

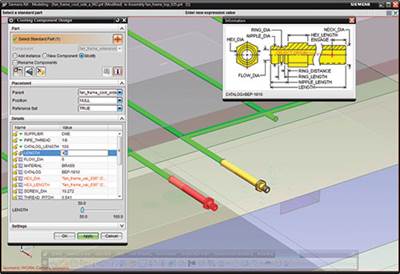

Read MoreIntegrating Electrode Production

How CAD/CAM can help make the design, machining and inspection of electrodes completely integrated.

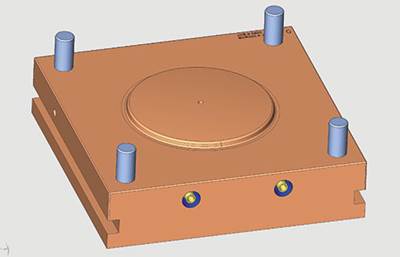

WatchRaising the Bar on Better

A look at one project to move away from traditionally customized moldmaking toward a level of complete automation that raises the bar on accuracy, repeatability and control.

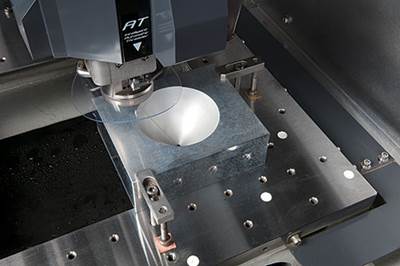

WatchTraditional Labor Values Meet Linear Technology

What GW gained was high reliability, improved speed/throughput without sacrificing accuracy or quality and a high level of satisfaction from the operators, on all the machines.

Read More

.jpg;maxWidth=300;quality=90)