Five Axis

Throwback Thursday: Flexible High-Speed Mold Machining

A throwback with helpful tips: Use this planning guide to identify the right double-column machining center to fit your mold machining needs.

Read MoreSpindle Head Offers Increased Stability on Milling Machine

Zimmermann designed the FZU five-axis gantry milling machine with the VH10 spindle head. The VH10 replaces the VH12, which is not a Zimmermann product.

Read MoreATC Provides Ample Workpiece Storage for Unmanned Operation of Machine

The 32-position Auto Work Charger on the Mazak Variaxis i-300 five axis vertical machining center accommodates workpieces up to 13.779" in diameter, 12.401" high and weighing as much as 135 lbs.

Read MoreNew Five-Axis Machining Giant Hits the U.S. to Tackle Large Machining Projects

Baker Industries installs an Emco Mecof PowerMill five-axis machining center, which is the largest and most versatile milling center in the Midwest Region and the first of its kind to enter the United States, to expand its capacity to service OEM and Tier 1 customers’ largest machining projects.

WatchTake a Look Inside Deep Hole Drilling

Do I have your attention with this shot? It’s the inside of a gun barrel. What does that have to do with moldmaking? More than you think when it comes to deep hole drilling your waterlines, cross hole drilling, and deep pockets at compound angles, and on one machine instead of three—boring, five-axis machining and deep hole drilling in one accurate yet approachable machine.

Read MoreLessons Learned in Deep Hole Drilling

Of course when it comes to deep hole drilling, the tooling, the fixturing and the automation are all essential, but the part that caught my attention during a recent UNISIG event was the focus on mold-specific industry solutions, especially its USC-M series machines that allow multiple operations to be performed on all workpiece sides with one setup.

Read MoreFive-Axis Rotary Table TAP Suitable for Small Vertical Machining Centers

Exsys Tool Inc. says that its five-axis rotary table tap enables users to upgrade vertical machining centers without incurring the expense of a new machine.

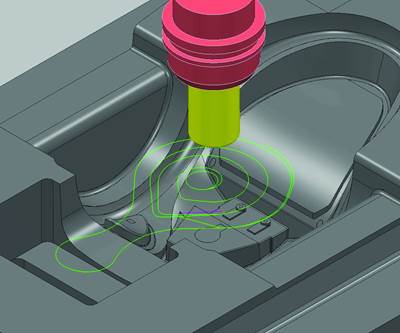

Read MoreCAM Tools Automate Programming, Aid Five-Axis Machining and More

The right software tools can help a shop realize the full potential of its workforce so that it can better meet increasing customer expectations.

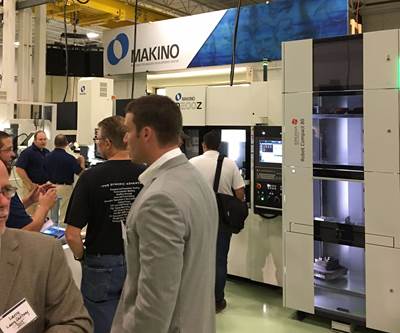

Read MoreMoldmakers Share Benefits of Makino Die/Mold Expo

Three mold manufacturers share their takeaways from the recent Makino Die/Mold Expo.

Read MoreThree Takeaways from Die/Mold Expo

What do you gain by attending events like the Makino Die/Mold Expo that was held last week at the company’s Technology Center in Auburn Hills, Michigan? I asked a few of the moldmakers I met there to share their personal takeaways.

Read More