Build

Ceramic End Mills Excel in High-Speed Roughing, Milling of Heat-Resistant Superalloys

Long-lasting, five-flute Cera-Cut end mills introduced by Emuge-Franken USA are designed to consistently tackle high temperature resistant metals and hardened tool steels.

Read MoreHigh-Feed Performance for Mold and Die Machining Operations

The Ingersoll NanoFeed indexable insert’s applicability for detailed, high-feed rest roughing operations offers mold builders optimized milling performance for miniature components and smaller part features.

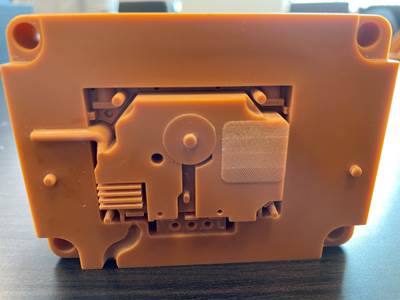

WatchTechnology and Sourcing Guide 2023: Mold Components

Mold components make the mold work and the mechanisms used to deliver a quality end product. Key components include mold bases, pins, ejectors, lifters, bushings, guides and alignment devices.

Read More5 Big Themes in Additive Manufacturing at Formnext Forum: Austin

As manufacturing advances with additive, the advance increasingly emphasizes these five themes.

Read MoreDiamond-Coated End Mills for Machining Electrodes

Adding on to Crystallume’s Standard Premium and Lightning coatings is Stealth, the company’s thinnest diamond coating for highly detailed moldmaking work.

Read MoreTechnology and Sourcing Guide 2023: Hot Runners

Hot runners deliver the material into the mold to make the part. These systems consist of hot halves, nozzles, gates and temperature controllers — all of which must be monitored, maintained and cleaned to guarantee a quality end product.

Read MoreHydro Chuck Toolholder Promises Precision When Heavy Milling

Precision cutting tool solutions manufacturer NT Tool presents Hydro Chuck Omega, designed to eliminate the common issues of chatter, deflection and pullout.

WatchSmall-Diameter End Mills Ideal for Mold and Die Industry

The carbide Inchmax series by U.S. Union Tool, with between 0.010 to 0.125-inch diameter ranges, is capable of milling a variety of materials.

Read MoreUniversal Presetting, Measuring Machine Aids Cutting Tool Assembly

Zoller’s »redomatic 600« machine and software programs drive productivity in mold building through maximized accuracy and efficiency in five-axis CNC machining operations.

Read MoreTechnology and Sourcing Guide 2023: Mold Materials

Proper selection of the appropriate mold material is critical to manufacturing a high-quality mold. Tool steel, aluminum, copper and alloys are some of the materials used.

Read More