Build

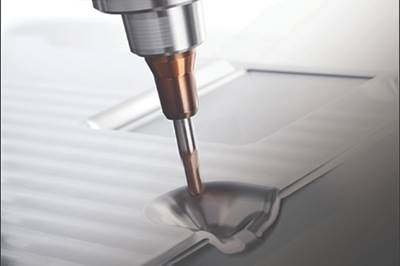

Drill Tailored to Challenging Materials Like Stainless Steel and Titanium Drilling

Guhring Inc. highlights the RT 100 InoxPro, a cutting-edge solid carbide drill tailored specifically for challenging materials like stainless steel and titanium alloys.

Read MoreDrilling and Turning Tool Expands Small-Diameter Tool Options

Tungaloy-NTK Inc. announces the expansion of its TungBoreMini series, introducing a new holder for a minimum machining diameter of ø8 mm (.315″).

Read MoreAn Integrated Desktop Approach to Mold Production

Versatile, scalable, additive machining and molding systems optimize moldmaking operations and support training initiatives.

Read MoreExpanded End Mill Line Offers Multi-Purpose Benefits to Moldmakers

Emuge-Franken USA announces it has expanded three-fold the range of TOP-Cut VAR, the company’s most popular multi-purpose high performance end mills.

Read MoreEnd Mill Delivers Maximum Cutting Volume for Steel Materials

Haimer USA highlights the upcoming Panther Mill, its latest innovation in high-performance cutting tools to benefit the machining processes beginning in 2025.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreModular Quick-Change Head System Benefits Various Applications

Iscar USA highlights its new modular quick-change head system for Swiss-type machines intended for turning, grooving, parting and threading applications.

Read MoreCollaborative Engineering Drives Quality Mold Solutions

Advanced engineering and tooling teams collaborate to train, design, develop and deliver high-quality, cost-effective molds efficiently, ensuring perfect parts and faster launches.

Read MoreAdditional Sizes for Tooling System to Streamline Mold Building

PCS Company introduces a range of new sizes to its Flexible Insert Tooling System (F.I.T.S.) in response to growing customer requests for more options to streamline mold building and their molding processes.

Read MorePCD Milling Cutters Reduce Cutting Forces and Vibration

Walter USA LLC offers the MP060, MP160 and MP260 milling cutters with brazed PCD cutting edges for machining aluminum, aluminum-silicon alloys, magnesium alloys, plastics and fiber composite materials.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)