3D Printing

Considerations for AM Powder for Tooling

The start of any good product is the raw material, and that includes additive manufacturing powder for tooling.

Read MoreWohlers Offers AM Course in Germany

Wohlers Associates, Inc. takes its course on design for additive manufacturing (DfAM) to Hamburg, Germany, June 13-14, 2019.

Read MoreCustom Mold & Design Chases Complex Mold and Production Part Projects with Top-of-the-Line Five-Axis, Screw, Mill/Turn, Additive and Molding Machines

Unique business model—with an eye on complex projects and an arsenal of machine technology to meet the required accuracy levels—raises the bar in mold and machined component manufacturing.

Read MorePushing the Limits of 3D Printing

Crest Mold Technology continually investigates additive technologies and seeks new ways to use it in moldmaking.

Read MoreStratasys Direct Manufacturing Expands Additive Metals Offering

Stratasys Direct Manufacturing expands its additive metals offering with the addition of VELO3D’s Sapphire 3D print system and Flow software.

Read MoreConformal Cooling: Not Just Faster Parts but Better Parts

EVCO Plastics has been offering DMLS conformal-cooled inserts for years and like many shops today, they outsource this work to mold builders who have expertise in DMLS.

Read MoreEvolve Additive Solutions Grows its Operations

Evolve Additive Solutions will expand its operations in Brighton, New York.

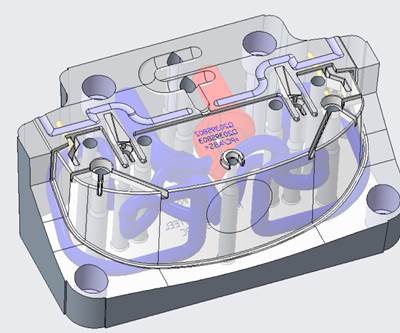

Read MoreAmerimold 2019 Update: What You Should Know about Additive Manufacturing for Conformal Cooling

This panel discussion will present in detail the different AM technologies available today, their advantages and disadvantages, and specific ways to implement these technologies without issue.

Read MoreWohlers Report 2019 Projects Growth in Additive Manufacturing

Wohlers Associates’ publication, Wohlers Report 2019, reports on additive manufacturing and 3D printing.

Read MoreHighly-Automated Tool Shop Achieves Efficient, Precise Medical Device Manufacturing

When a basketball player needs a knee replacement, standard implants simply won’t do. With a total of 18 different additive manufacturing systems, the Aesculap division of medical company B. Braun is the place to go to have custom implants printed to size. However, the highly-automated tool and mold shop has much more to offer when it comes to producing injection molds, complex progressive dies as well as prototypes and fixtures for series production.

Read More