Turning Insert Geometry Delivers Expertise in Machining Medium Steels

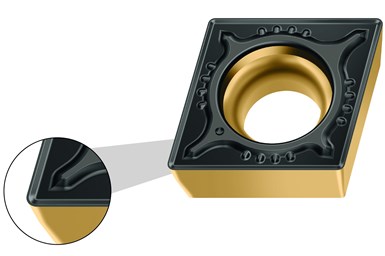

The MP6 geometry introduced by Walter USA combines features for efficient chip breakage and a strong cutting edge.

Walter USA introduces the MP6 geometry for turning operations. With the MP6, Walter rounds off its range for medium machining of steel (ISO P). The geometry also has secondary applications in stainless steels, cast iron and super alloys (ISO M, K, S). The MP6 combines features for medium machining, such as a positive rake angle, with those of roughing inserts; for example, a strong cutting edge. According to Walter, this makes it the perfect link between the existing MP4 geometry for medium machining (with optimized chipbreaking on soft steels) and the RP4 for roughing operations (with tough cutting edge for high feeds). The straight cutting edge of MP6 also makes it an ideal geometry for internal boring operations.

To cover the widest possible range of applications, Walter offers the MP6 geometry in CCMT, DCMT, TCMT and VBMT basic shapes. Its short protective chamfer, which is characteristic of roughing inserts, is said to ensures a high strength of cutting edge, even in challenging conditions; for example, when machining forged parts or components with interrupted cuts. The 18° positive rake angle ensures excellent chip control during medium machining.

To prevent vibration, such as when machining thin-walled components, Walter has given the MP6 geometry an open chipbreaker groove. This reduces the cutting pressure even when cutting at a higher depth of cut. This also makes the MP6 ideal for an unstable workholding setup and components with long overhangs, such as during internal turning. The new Tiger-tec Gold grades also have a positive impact on tool life. The WPP10G, WPP20G and WPP30G grades are adapted to different operating conditions, thereby improving tool life and performance across a broad range. Walter specifies feeds from 0.004-0.014". and depths of cut from 0.016-0.157" as the range for the machining parameters.

Related Content

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

.png;maxWidth=300;quality=90)