VMC Line Offers Jig Milling Accuracy with Machining Center Productivity

Mitsui Seiki offers machining center technology and jig borer precision in one machine with its J-series CNC vertical machining centers.

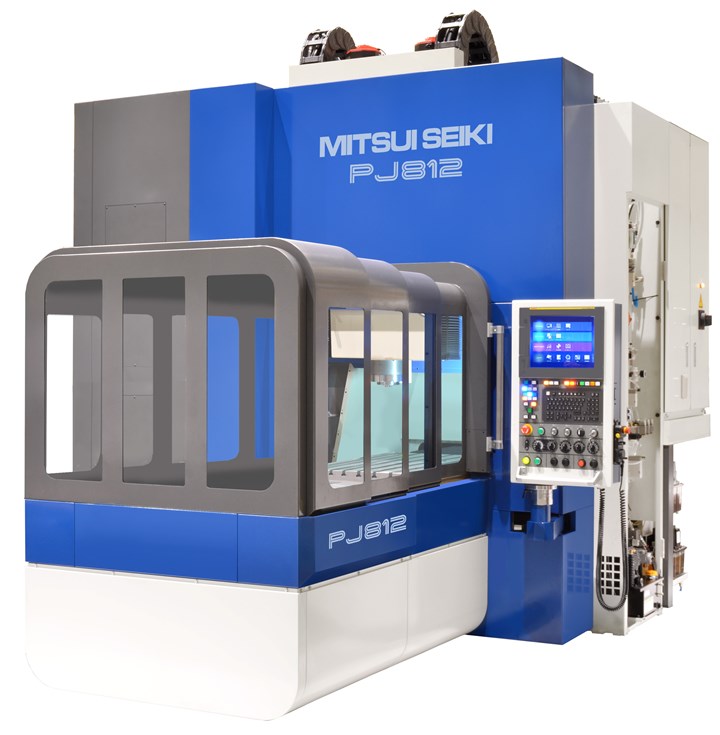

Photo Credit: Mitsui Seiki

Mitsui Seiki has launched a new series of CNC vertical machining centers called the “J” series for “Jig,” which are ideal to machine medical, optical, mold & die and aerospace parts.

The line provides positioning accuracy and repeatability of +/- 1µm. A thermal compensation system employs sensors on the machine faceplate and inside the spindle to minimize the effects of temperature changes on part accuracy and cut temperature-generated displacement by 60%. Z-axis thermal growth and deflection is also reduced by 30%. Cooling systems for slide way lubrication and ball screw cores stabilize axis feed precision.

Mechanical design features that maximize machine rigidity and accuracy include hardened and ground tool steel box slideways, as well as contact elements that enhance acceleration, reduce stick-slip and allow for feed accuracy. Further, static rigidity of the Z-axis is said to be improved to more than six times that of conventional Z-axis arrangements.

According to Mitsui Seiki, these heavy-duty, ultra-precision machines allow for more complete machining of precision components including precision boring, milling, drilling and tapping.

The line includes four basic machines to satisfy a broad range of workpieces:

- PJ812 (PJ for “Profile Jig”): Travels X-1200mm, Y-800mm, Z-500mm. Max work size is 1200mm x 800mm. Table load is 1500 kg. Spindles are offered from 10,000-30,000 rpm. ATC 60, 90, 120 tools.

- J1220: Travels X-2000mm, Y-1250mm, Z-500mm. Max work size is 2200mm x 1500mm. Table load is 3000 kg (4000 opt). Spindles are offered from 10,000-15,000 rpm. ATC 60, 90, 120 tools.

- J1230: Travels X-3000mm, Y-1250mm, Z-500mm. Max work size is 3000mm x 1500mm. Table load is 3000 kg (4000 opt). Spindles are offered from 10,000-15,000 rpm. ATC 60, 90, 120 tools.

- J1625: Travels X-2500mm, Y-1600mm, Z-500mm. Max work size is 2700mm x 1700mm. Table load is 6500 kg. Spindles are offered from 10,000-15,000 rpm. ATC 20, 60, 90, 120 tools.

All of the machines feature a full enclosure and various coolant system options.

Related Content

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.