Universal Metrology Software Connects All Measurement Devices to One System

NextMeasure introduces a metrology software solution that is capable of seamlessly integrating all portable measurement devices on one platform for ease of integration, upgrading and switching tools.

NextMeasure, a startup measurement software company that puts the user experience first, highlights how its universal metrology software enables highly efficient measurement systems so that moldmakers are able to inspect and measure any and all molds in any location, at an affordable price point.

The offered software is different from other traditional metrology options, NextMeasure notes, which are often tied to specific brands. This makes it challenging to add new devices, swap users and evaluate upgraded capabilities. NextMeasure’s software, on the other hand, is said to seamlessly integrate all portable measurement devices on one platform for ease of integration, upgrading and switching tools, making it highly flexible.

For dimensional control or mold assembly, a variety of devices can be connected, from measuring arms to laser trackers. NextMeasure also has the capacity to combine probe point analysis and point cloud, with GD&T to evaluate all tolerances, positions, flatness, roundness and a variety of shapes and sizes.

Examples of devices that are compatible with NextMeasure software and can be used together include:

- HandySCAN (by Creaform): Ideal for color mapping and reverse engineering, HandySCAN is reported to be fast and accurate.

- Quantum Arm (by Faro Technologies): Designed for scanning and probing circles, planes and slots, the Quantum Arm has the ability to evaluate GD&T and is useful for complex parts, tools or molds.

- ACE Arm (by Kreon): The easy-to-use Kreon Ace measuring arm is well-suited for contact and noncontact 3D measurements.

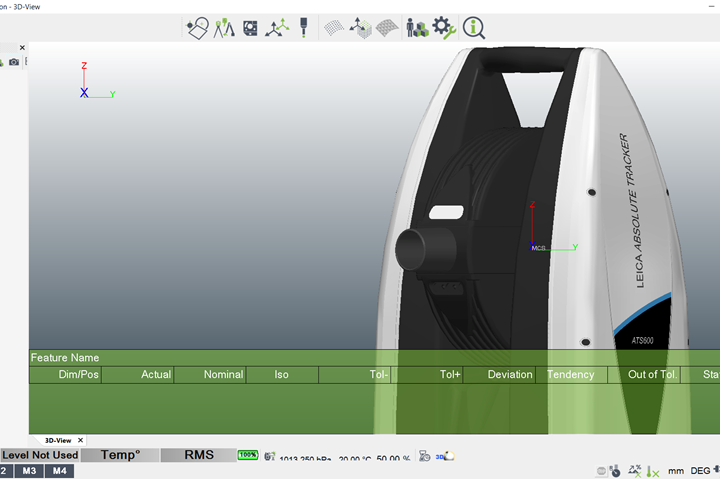

- Tracker ATS600 (by Leica): Combining reflector measurement and direct scanning capabilities this tool delivers all-round performance for large-scale measurement tasks.

“Never before have creators had this much access to different devices on a single system,” Clement Martinese, software quality control at NextMeasure, contends. “Not only does this provide them with optimal measurement results for each project they are working on, it also eliminates costs as our customers can purchase devices on a need-to-need basis without having to upgrade their entire system.”

NextMeasure provides support through a series of step-by-step tutorials, all available on its website, for rapid onboarding and integration within the team. Real-time online support with a direct chat option solves questions efficiently and effectively. Screen sharing and control for fast problem solving with the NextMeasure tech team is an additional option offered.

Related Content

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

Surface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.